In the Industrial Internet of Things (IIoT) world, there’s been a lot of buzz around edge computing and its practical applications. Industrial automation systems are naturally edge computing solutions due to reliability and speed requirements. Automation systems can be viewed as "things" in the IIOT. For those architecting enterprise analytics or MES systems, however, the decision of where to locate data collection and analysis resources in a network architecture gets a little more gray.

Here are five things to consider when deciding how to divide and locate computing assets in an IIOT and analytics system.

In a centralized cloud computing architecture, the “edge” of the network is traditionally where data is collected from multiple remote locations (such as sensors, controllers, and servers). Rather than transmitting everything back to the cloud, edge computing is simply the concept of immediately processing, analyzing, and even acting upon the data at its source.

What does that mean for IIoT systems producing vast amounts of information at increasing speeds? Low latency. Edge computing solutions allow us to capture and analyze real-time data at high volume and high data rates.

For example, at a solar power plant, solar irradiance information can be almost instantaneously used to adjust inverter output or panel trajectory using edge computing. Industrial control systems function this way naturally and have always lived on the edge. By skipping the middleman and not streaming the information to the cloud or centralized SCADA systems first for processing, benefits include:

· Faster decision making and response time to failures

· Optimized production with less lag

· Risk mitigation for network connectivity and bandwidth issues

The decision of whether or not to live on the edge is not always obvious, and it requires thoughtful design to get it right. Based on our expertise and experience with implementing edge computing, we’ve compiled a list of five design considerations for your industrial control or manufacturing system:

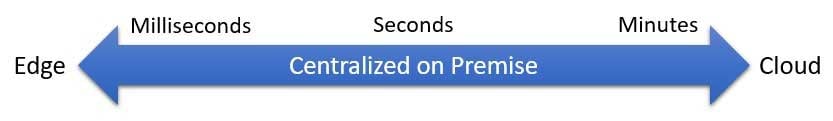

1. Data Interaction and Response Time

What is the level or speed at which you need to analyze the data at the source and make decisions based on the insights? Machine control and safety related systems should always be kept on the edge even if the control loops are relatively slow. For everything else, this becomes a question of response time. The further computing resources are from the edge, the slower the possible response/analysis time for new data.

2. Connectivity and Data Transfer

What data should be processed at the edge, and what data can be processed centrally? Bandwidth and connectivity considerations can play a major role in these decisions. If your available bandwidth is low and unreliable, you will need to keep more processing on-premise. If you have fast, reliable connections, you can move more off-premise. Data transfer protocols such as MQTT can help make efficient use of bandwidth.

3. Compliance, Regulation, and Cyber Security Policies

Is your infrastructure properly architected with all the regulations and cyber security policies in place to ensure safety, best practices, and system hardening? Any network, even one incorporating cloud resources, can be very secure if it’s designed and configured properly. Your level of comfort here will dictate more what data you put off premise than how much.

Download our white paper to read more about cyber security concerns.

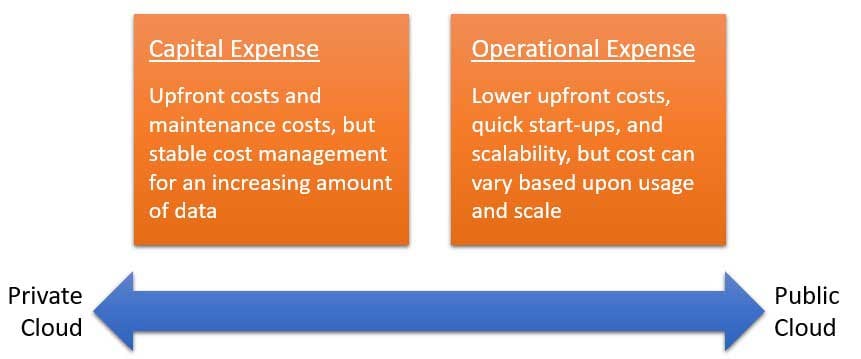

4. Public vs. Private Cloud

What is the cost-benefit analysis of using the public cloud (from various providers) versus the private cloud (from private data centers), and which is most appropriate for your company’s needs and budget?

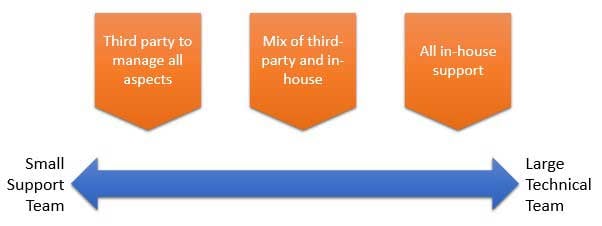

5. Technical Skillset

Does your team have the skillset to architect such a system? If not, you may need to select a third party partner to design, implement, and maintain an edge computing infrastructure.

A deep dive into each of the above points may be necessary before making any major decisions about applying edge computing solutions to your system. Contact us today to find out how our team of industrial automation experts can help you develop a complete edge computing system – from the sensors and controllers on the edge all the way up to analytics in the cloud!

Comments