Food & Beverage Automation

Savor the Flavor of Food & Beverage Automation

The Industrial Internet of Things (IIoT) has opened up new possibilities for businesses in the food and beverage industry. But without the right support, incorporating these cutting-edge technologies into your existing systems might feel like biting off more than you can chew.

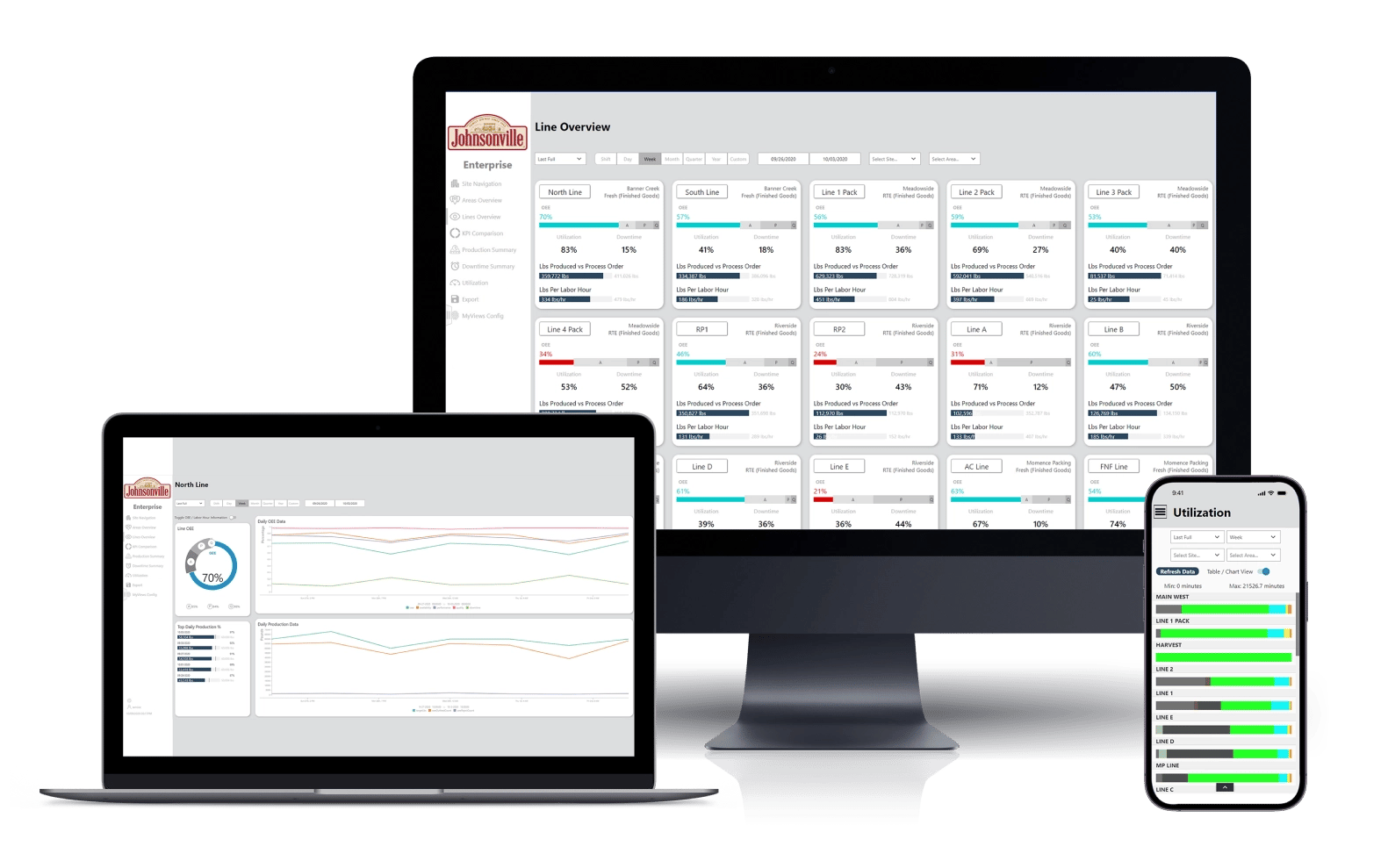

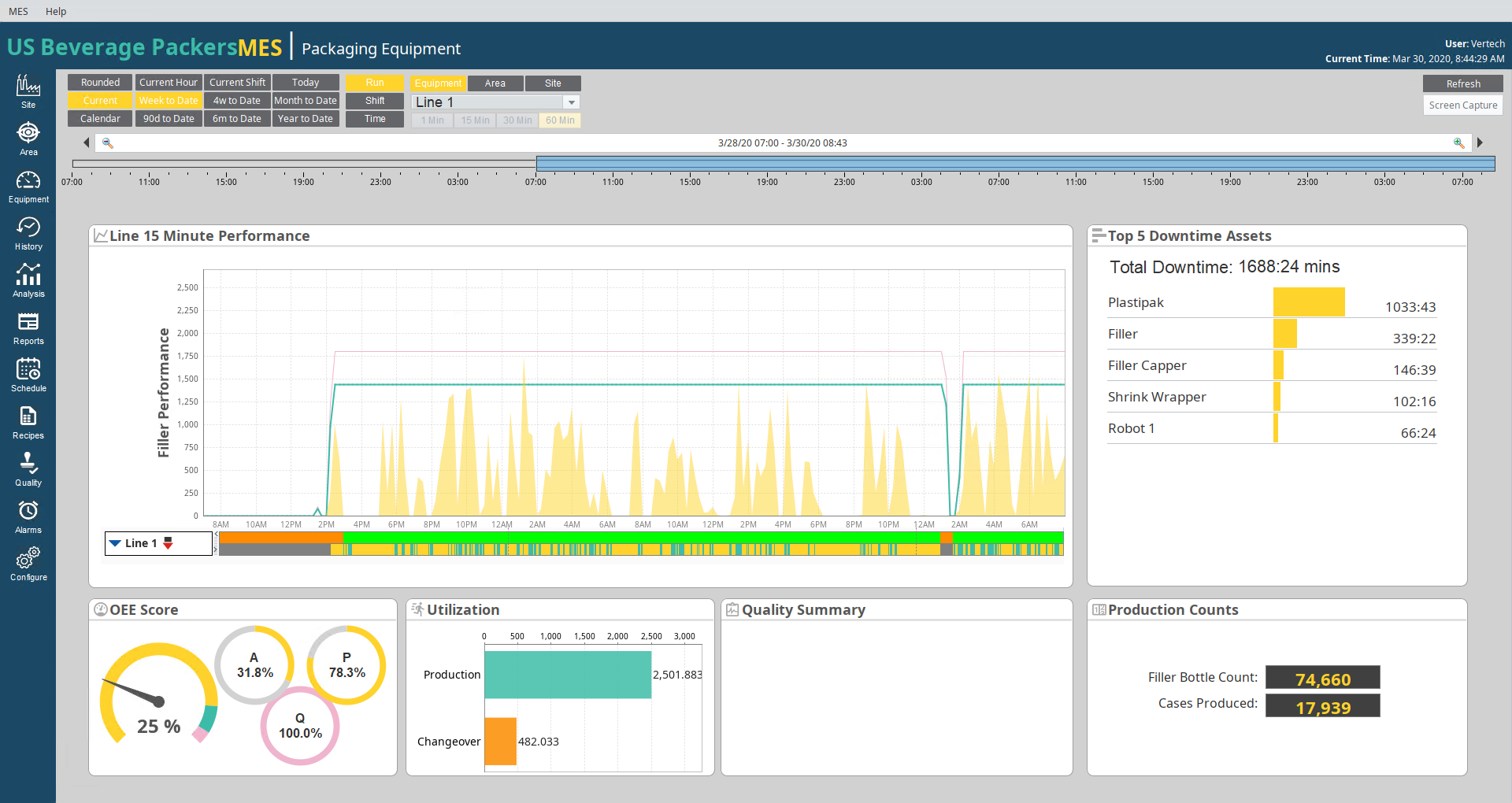

That’s where Vertech comes in. We develop custom MES and SCADA solutions for distillers, brewers, producers of dairy and dairy alternatives, co-packers, and more to modernize and digitize their existing systems.

Whether you’re looking to optimize production, improve data accessibility, ensure product consistency, or increase traceability, our experts are here to put automation on the menu.

- Beautiful, Intuitive Screens

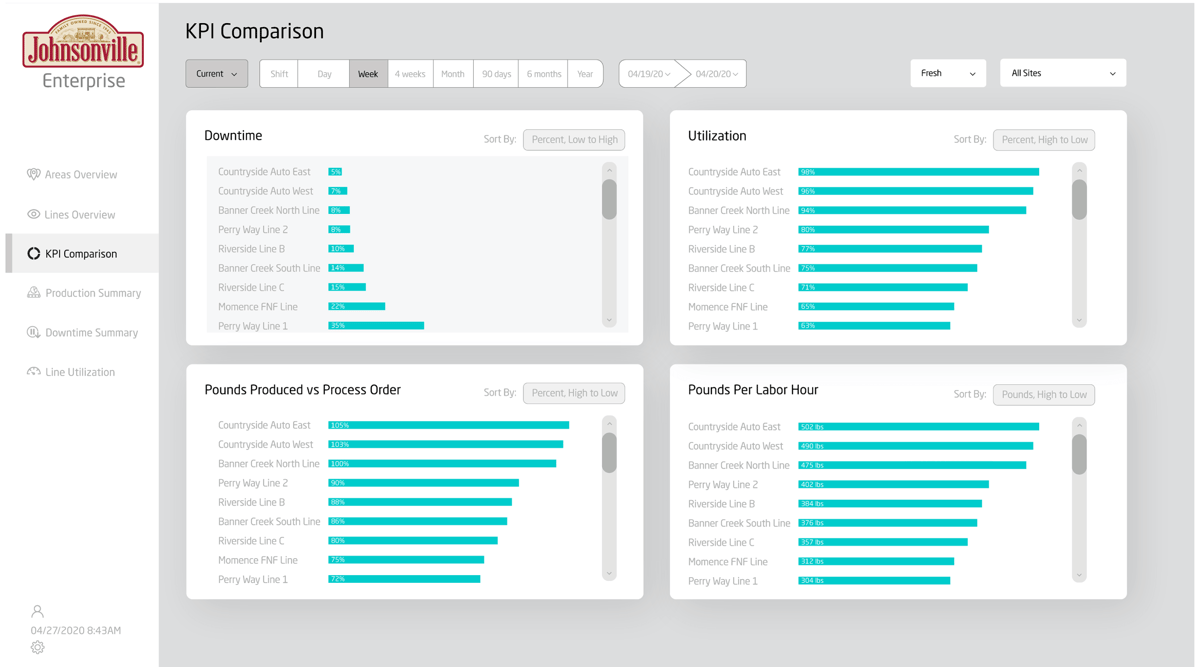

- Dialed-In KPIs with Real-Time Reporting

- Flexible, Customized Solutions

Serving Up Real-Time Insights & Process Control

Inventory & Traceability

With our track & trace and product genealogy solutions, you can increase production transparency, monitor material usage and yields, and map the path materials take throughout the production process. Better visibility tastes sweet!.webp?width=65&height=65&name=Layer_1%20(1).webp)

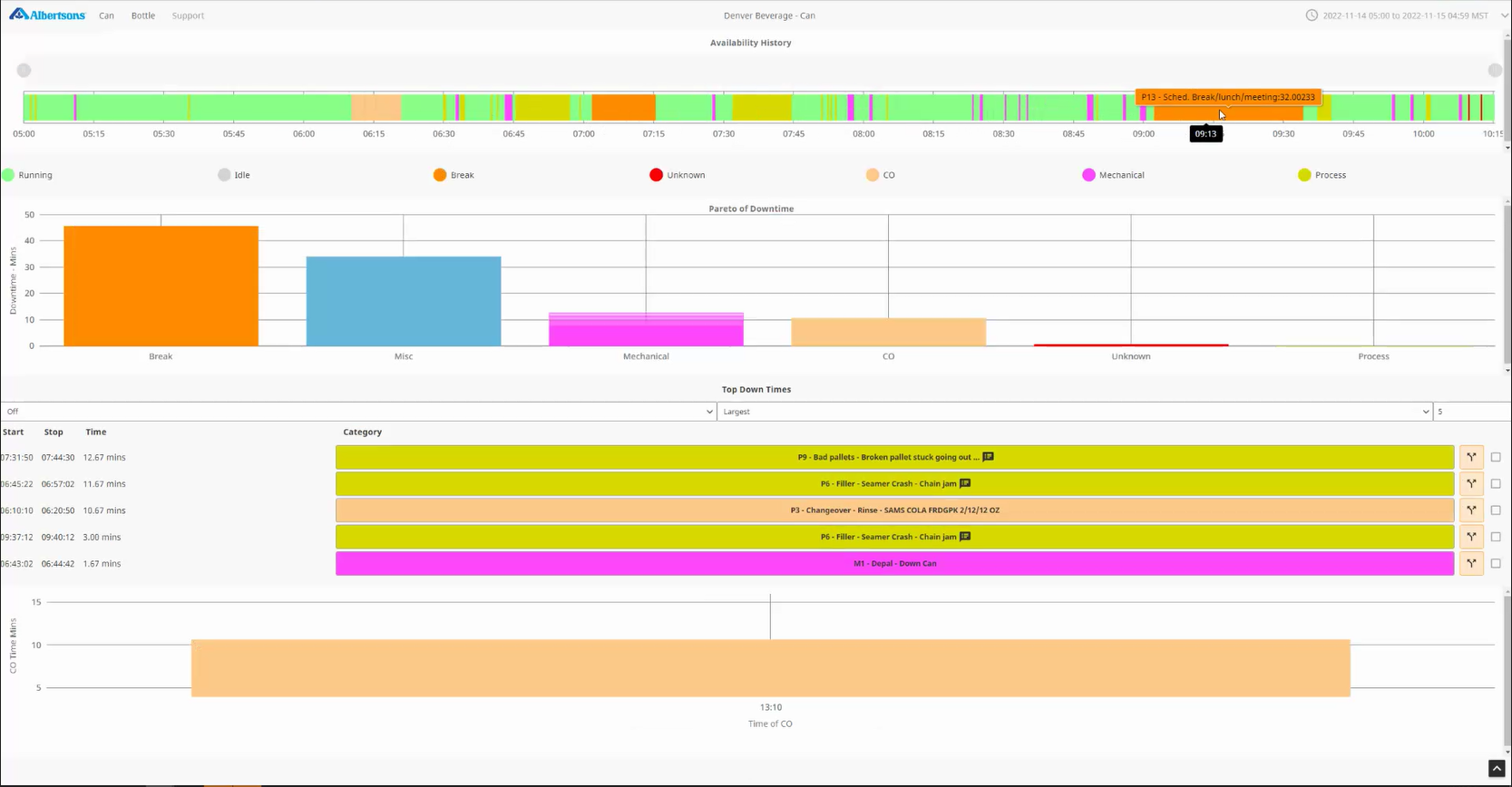

Efficiency & Overall Equipment Effectiveness (OEE)

Craving efficiency? By closely monitoring KPIs, Vertech can help you identify opportunities for workflow adjustments, network improvements, and more, so you can get more out of your existing assets. We also implement systems that identify the best time to perform preventative maintenance so your equipment works better for longer.

Process Automation (SCADA)

Manual processes leaving a bad taste in your mouth? From programming individual devices and PLCs to ensuring safe and secure integration between the plant floor and the enterprise, we offer comprehensive, platform-agnostic automation solutions..webp?width=65&height=65&name=Layer_1%20(2).webp)

ISA-88-Compliant Batch Management

Our batch management solutions integrate with existing equipment and software to ensure consistent product quality. Plus, we separate the code from the manufacturing process so operators can quickly configure the entire line using pre-saved configurations. It’s a recipe for success.

.png?width=1200&height=668&name=Frame%20143(1).png)

Some Of Our Projects

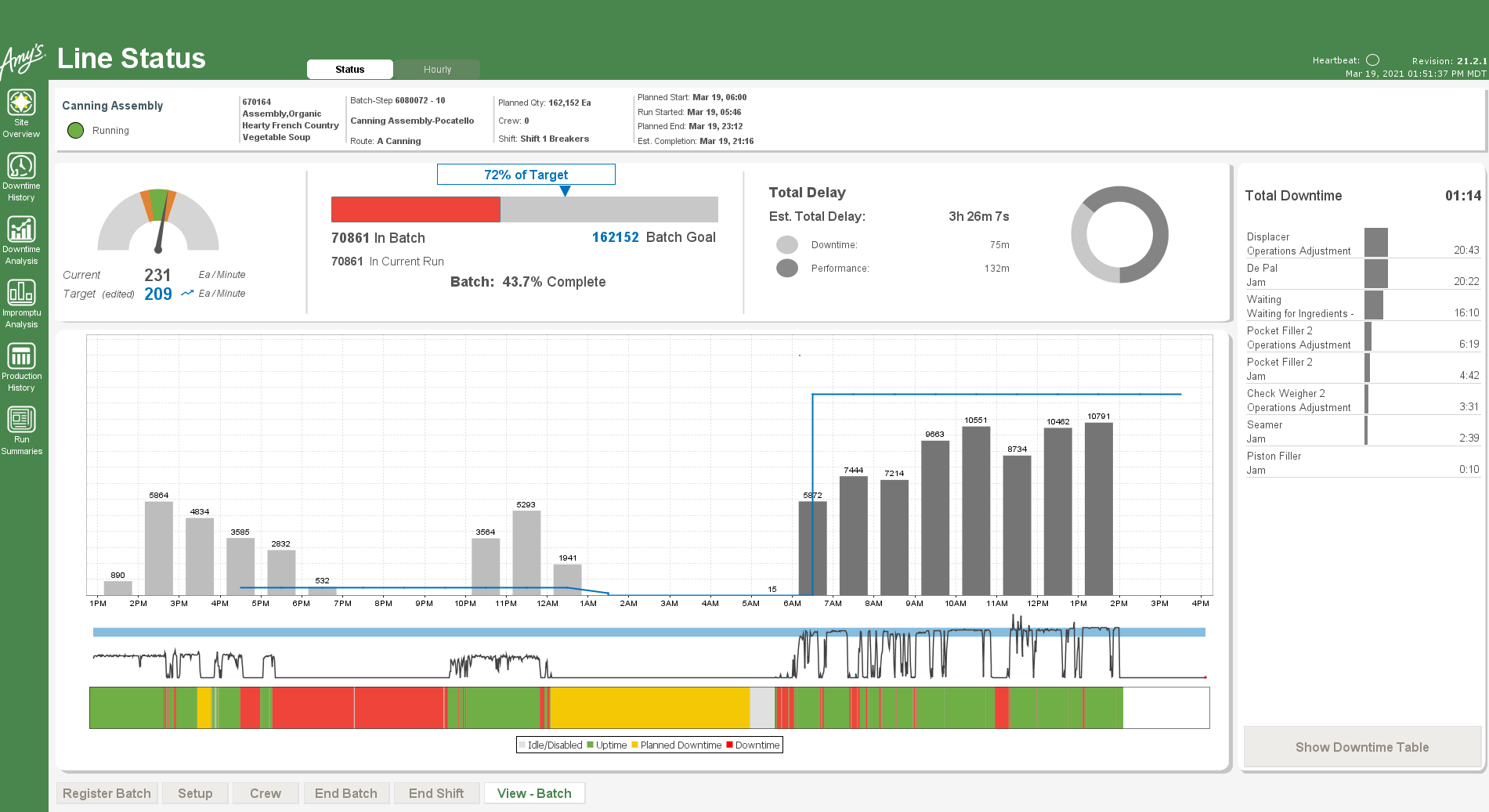

Amy’s Kitchen replaced their high-cost software with an improved OEE solution that fit their exact process and provided flexibility for future growth.

“Since the start of the project, we’ve built this as a centerpiece for best-in-class. Vertech provided us with best-in-class software that integrated well within the whole manufacturing facility.”

“Before the system was implemented, we relied on paperwork to track everything. I now have records of everything that goes on — tank transfers, [start and end] times, weight readings, inventory readings — and I have it all in real time.”

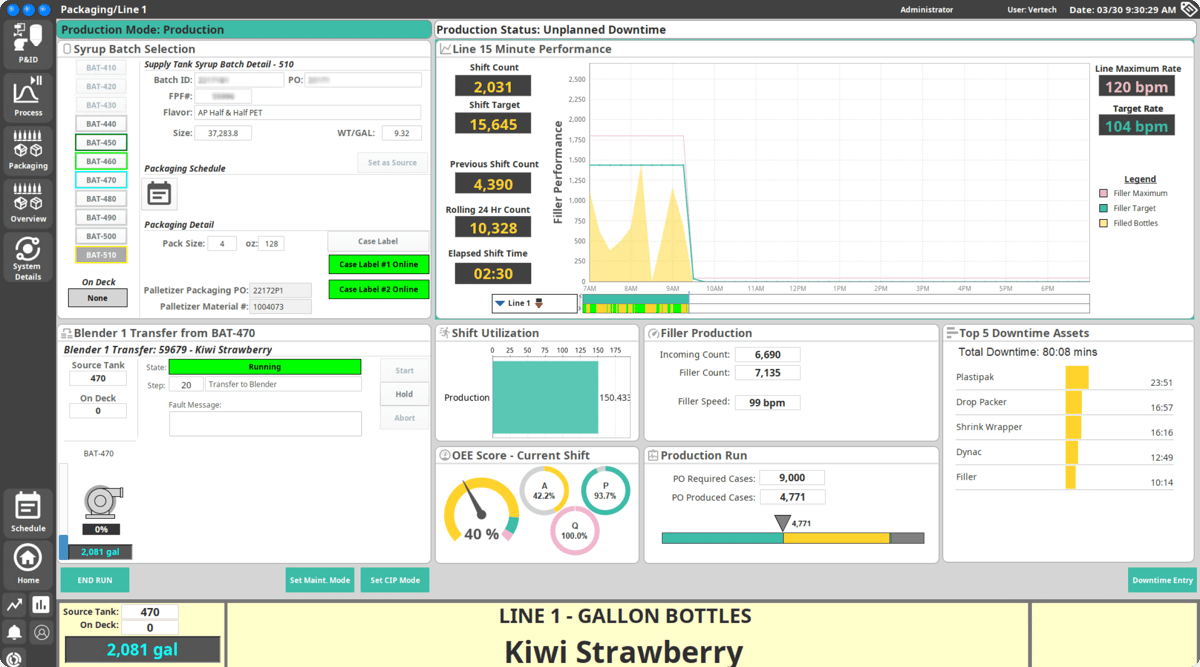

"The operator screens enabled our operators and supervisors to get a quick idea at a glance of generally how the run is going and if you are on track to finish production on time. From the manager screens, I was able to keep an eye on things from my office and see if there is a problem that is going on so I can make needed changes.”

Some Companies We’ve Worked With

.png?width=122&height=83&name=arizona-tea-font%20(transparent%20background).png)

Vertech At Your Service

At Vertech, we’re here to reduce your operational stress. We love designing human-focused MES, SCADA, OT and controls solutions that are a joy to use. The food and beverage industry is our bread and butter, and Ignition is our specialty.

So send us a message! Our engineers are happy to answer your questions or jump right into what’s happening on your plant floor.

Ready To Take Control?

Send us a message if you want to take your plant operations to the next level.

.png?width=2000&height=1416&name=whitepaper-img(1).png)

White Paper

7 SCADA Design Components to Maximize Productivity

In this white paper, we take a deep dive into how to use excellent software design to enhance your high-performance SCADA system, minimize time-wasting traps, and increase overall plant profitability.

.jpg?width=1890&height=1400&name=four-roses(1).jpg)