Control Panel Design & Manufacturing

.png?width=382&height=300&name=panel-design-hero(1).png)

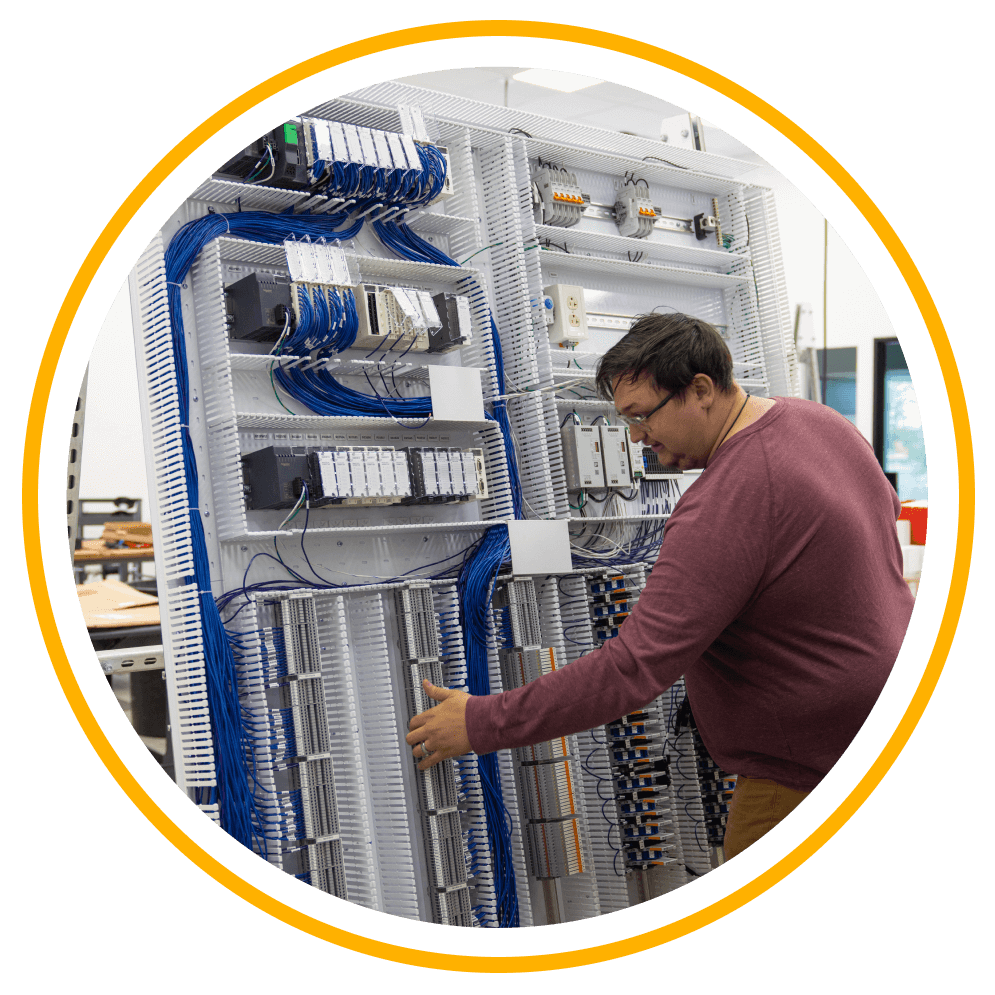

Comprehensive design-build services

We design and build clean, reliable control panels that provide a robust foundation for your operations. Don't expect a box of loose parts! Our panels are carefully designed, built, and delivered.

We start with meticulous design drawings. Then, we build your control panels in-house in our modern, UL-certified panel shop. This enables us to deliver a top-quality and cost-effective product that integrates seamlessly with our automation services.

And most importantly, they just work!

Built with the best

.png?width=218&height=60&name=autocad-electrical-no-year-lockup-stacked-screen%201(1).png)

.png?width=120&height=60&name=nvent-hoffman-logo%201(1).png)

.png?width=189&height=60&name=UL508A-logo%201(1).png)

.png?width=211&height=60&name=UL698A-logo%201(1).png)

.png?width=109&height=60&name=csia-certified%201(1).png)

Panel services

Panel Fabrication

Our UL 508a and UL 698a certified manufacturing facility guarantees exceptional quality and competitive pricing for industrial control panel fabrication. We specialize in turnkey projects and OEMs, accommodating panels of all sizes and production volumes.

Our state-of-the-art Steinhauer Modcenter 293 enables efficient, accurate production with precise panel cutouts and efficient back-panel drilling and tapping.

Upon completion, each panel undergoes a meticulous 42-point quality check, including point-to-point wiring, power testing, and cleanliness inspections. We deliver flawless control panels on time, every time.

Electrical Design Services

Our expert designers use AutoCAD Electrical to create comprehensive, professional drawing packages for a wide range of industrial control panels. We can also create loop diagrams, network diagrams, conveyor layout drawings, and other industry-specific process drawings.

Need support for a system upgrade or facility expansion? We offer on-site documentation services, working closely with technicians to accurately document existing internal and field wiring. For projects in Arizona, we also offer PE-stamped drawings for voltages up to 480VAC.

.png?width=497&height=497&name=panel-services-img(1).png)

.png?width=1000&height=652&name=3_900x694-Landing-Page-Great-Re-Engagement%201(1).png)

Case StudY

Upgrading an Aging Control System with Modern Tech

Learn how new automation control systems have helped two wastewater treatment facilities prepare for the future.

Why Vertech

Our panel design and manufacturing services are truly comprehensive. We handle everything: documenting your existing equipment and systems, designing new control panels and MCPs, creating industry-specific process drawings, and building and testing your control panels in-house.

We’re a world-class control panel provider, but we’re a lot more than that! Vertech is your one-stop shop for turnkey industrial automation solutions, including PLC, HMI, and SCADA programming, manufacturing execution systems (MES), operations technology, data analytics, and much more.

Ready to See the Difference?

Click to start the conversation with our team about your control panel design goals and needs.

.png?width=1200&height=942&name=support-hero(1).png)

FAQs

What do I need to consider when designing a UL-508A compliant panel?

UL certifies individual components as either “UL listed” or “UL recognized.” Generally speaking, when designing a UL-508A compliant panel…

- UL-508 listed components can be used freely.

- UL-508 recognized components can be used, but only within the manufacturer’s installation specifications.

- Non-listed components or components that are listed only under different UL standards are not permitted unless followed by a specific process and procedure.

To learn more, check out this blog post.

How do I plan a control system migration?

How do I implement redundant PLCs?

First, research the manufacturer and model of PLC to ensure they support full redundancy. In addition to the second PLC, you’ll need a separate rack, separate power supply, and communication cards. Make sure your maintenance staff is trained and practiced in the recovery process after a controller failure. Explore more tips here.