Digital Plant

The power of a digital factory

Our Digital Plant Technology Partners

Analytics

We've got data analytics down to a science, ensuring flawless inventory and traceability, precise production tracking, track and trace, and seamless reporting and compliance. Plus, our snazzy dashboards make it easy to keep an eye on business KPIs and alarms.

Site control & SCADA

We cover everything from user-friendly human-machine interface (HMI) design to real-time monitoring, precise system control, and smart reporting. We've got your back with historical data trends, helpful dashboards, and mobile solutions to keep you in the loop.

Order execution & MES

We make your production process a whole lot simpler and smarter with top-notch manufacturing execution systems (MES) / manufacturing operations management (MOM), recipe and batch management, quality control, precise scheduling, and streamlined workflows.

Enterprise solutions

Know exactly what's going on across your entire enterprise with seamless fleet management, savvy multi-site analytics, easy mobile access, simple ERP integration, value-focused MES solutions, and contextualized dashboards.

Efficiency

We're all about boosting your overall equipment effectiveness (OEE), keeping your equipment shipshape with predictive maintenance and computerized maintenance management systems (CMMS), and serving up intuitive dashboards that help you stay on top of KPIs and production tracking.

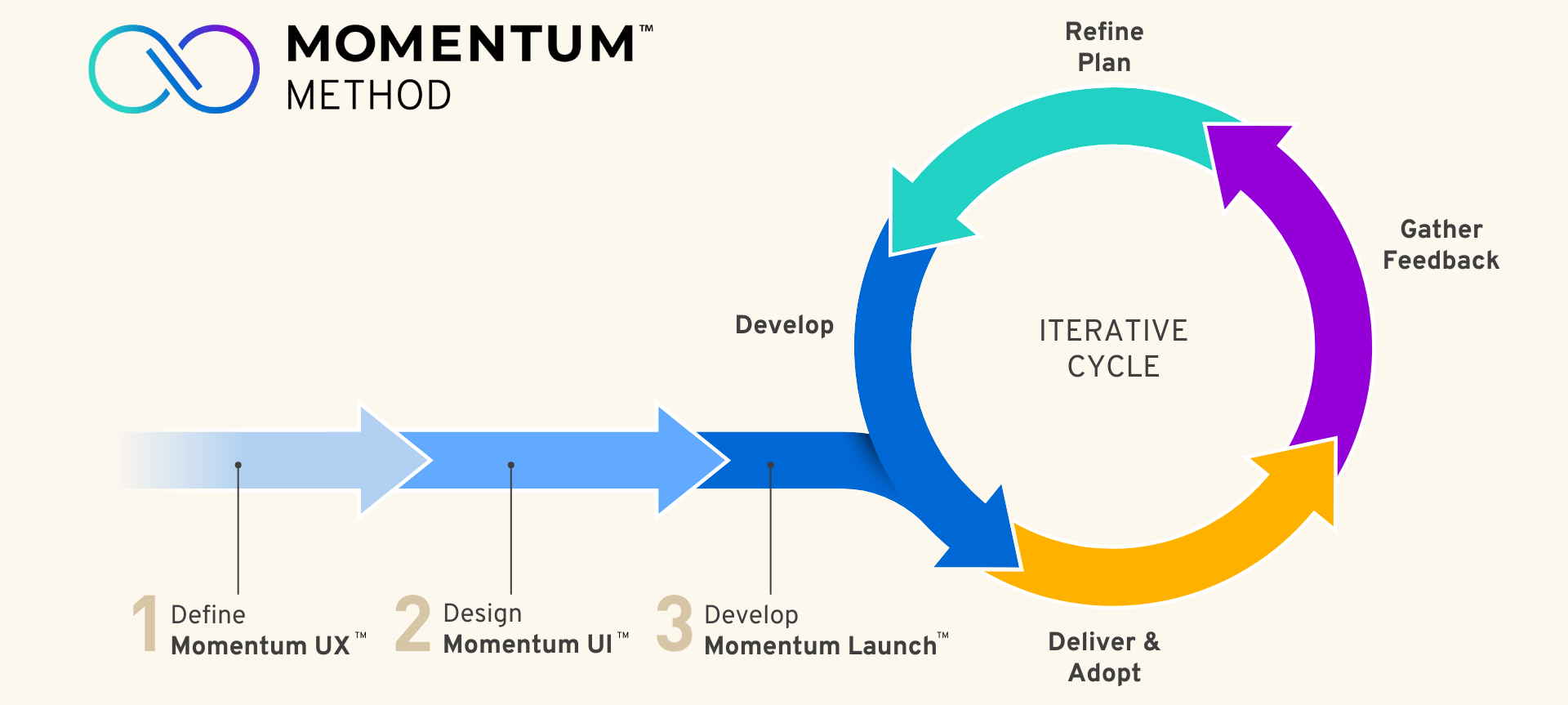

Our Process Accelerates Results

Real-world Success Stories

“Working with Vertech was a great culture fit. They were great communicators, passionate, innovative, and able to provide solutions to any problem we had.”

“Since the start of the project, we’ve built this as a centerpiece for best-in-class. Vertech provided us with best-in-class software that integrated well within the whole manufacturing facility.”

Vertech harnessed the power of Ignition Perspective to significantly enhance the SCADA system for the Warren, Simpson, and Butler County Water Districts.

Whitepaper

Unlock the Full Power of Your Data with UNS & UAF

Data drives efficiency, innovation, and operational excellence—IF you can manage and analyze that data across disparate systems. Download the white paper to learn how to implement scalable, flexible data architecture.

Why Vertech

.png?width=498&height=498&name=img-247-supp(1).png)

Digital plant woes? Make your problems our problems.

We love building bulletproof digital plant solutions. And we have the industry experience to prove it, from water/wastewater and solar projects to manufacturing, data centers, food & beverage and more.

Our expert staff of Ignition engineers can help you elevate your automation processes with tools that optimize operations, enhance efficiency, and streamline business management.

.png?width=498&height=498&name=img-247-supp(1).png)

Maximize Your Digital Plant.

Click to talk to our team about improving your data management, visibility and plant efficiency.

.png?width=1200&height=942&name=support-hero(1).png)

FAQs

How does SCADA screen design impact plant productivity?

What are the most essential MES tools for plant productivity?

We recommend implementing the following MES tools:

- Overall Equipment Effectiveness (OEE)

- Downtime Tracking

- Data Entry Automation

- Track and Trace

- Asset Management

- Predictive Maintenance

- Production Scheduling

- Recipe Management

- Statistical Process Control

For a deep dive into each of these tools and how they can improve performance, download our white paper, 9 MES Tools Every Plant Manager Needs.

How can I reduce risks during a control system migration?

To reduce risk, be sure to decide on your approach (hardware-only or hardware and software), prioritize the upgrades that are most important, and create a comprehensive upgrade plan that includes risk identification and mitigation strategies.

For a deeper dive into risk mitigation, download our white paper, 5 Risk Mitigation Techniques for Control System Upgrades.

How can I ensure a successful MES implementation?

First, you’ll need to prepare for change and get buy-in for the project. You’ll also need to create a process map and detail all the data you are hoping to get out of your MES system, and schedule workshops throughout the implementation process to assess your progress. Check out this blog post for more helpful strategies.

What should I consider when selecting an OEE solution?

The most important initial consideration is whether you need a custom OEE software solution or a point solution. Custom OEE software solutions are developed using a generalized software platform, while point solutions are specific to a single application. Check out this blog post to learn more.

What does it mean to digitize my factory?

From better reliability to easier scalability and integration, there are numerous reasons to incorporate cloud technology into your plant floor operations. Download our white paper to explore common benefits and concerns, as well as real-world use cases connecting to the cloud.

What are the first steps to becoming a fully digital factory?

First, you’ll need to prepare your employees for change and establish a project management plan. Then, once you’ve selected your MES software, you can start making the transition to digital one process at a time. For a deeper dive into each step, download our digital factory white paper.

How can I maximize the potential of my plant’s data?

Unified Namespaces (UNS) and Unified Analytics Frameworks (UAF) can help establish seamless data communication between disparate systems and unlock the true potential of your data. Download our UNS/UAF white paper to learn more.

.jpg?width=1890&height=1400&name=sb-energy-1(1).jpg)

.jpg?width=1890&height=1400&name=arizona-img1(1).jpg)

.jpg?width=1890&height=1400&name=warren-img(1).jpg)