Manufacturing Execution

Systems (MES)

Better data. Better decisions. Better performance.

Maximize Production With Bulletproof MES

Want to go from machine-based automation to a fully connected digital plant? How about transforming disparate software and manual calculations into seamless real-time data reporting?

We’re passionate about MES solutions because we’ve seen what’s possible. Our MES / MOM systems are designed to identify efficiency and quality issues, improve production visibility, seamlessly execute production tasks, and provide top-tier data analytics. Here’s to faster business decisions and a smoother plant floor.

What is MES?

.jpg?width=2866&height=1596&name=img-mes(1).jpg)

Manufacturing Operations Done Right

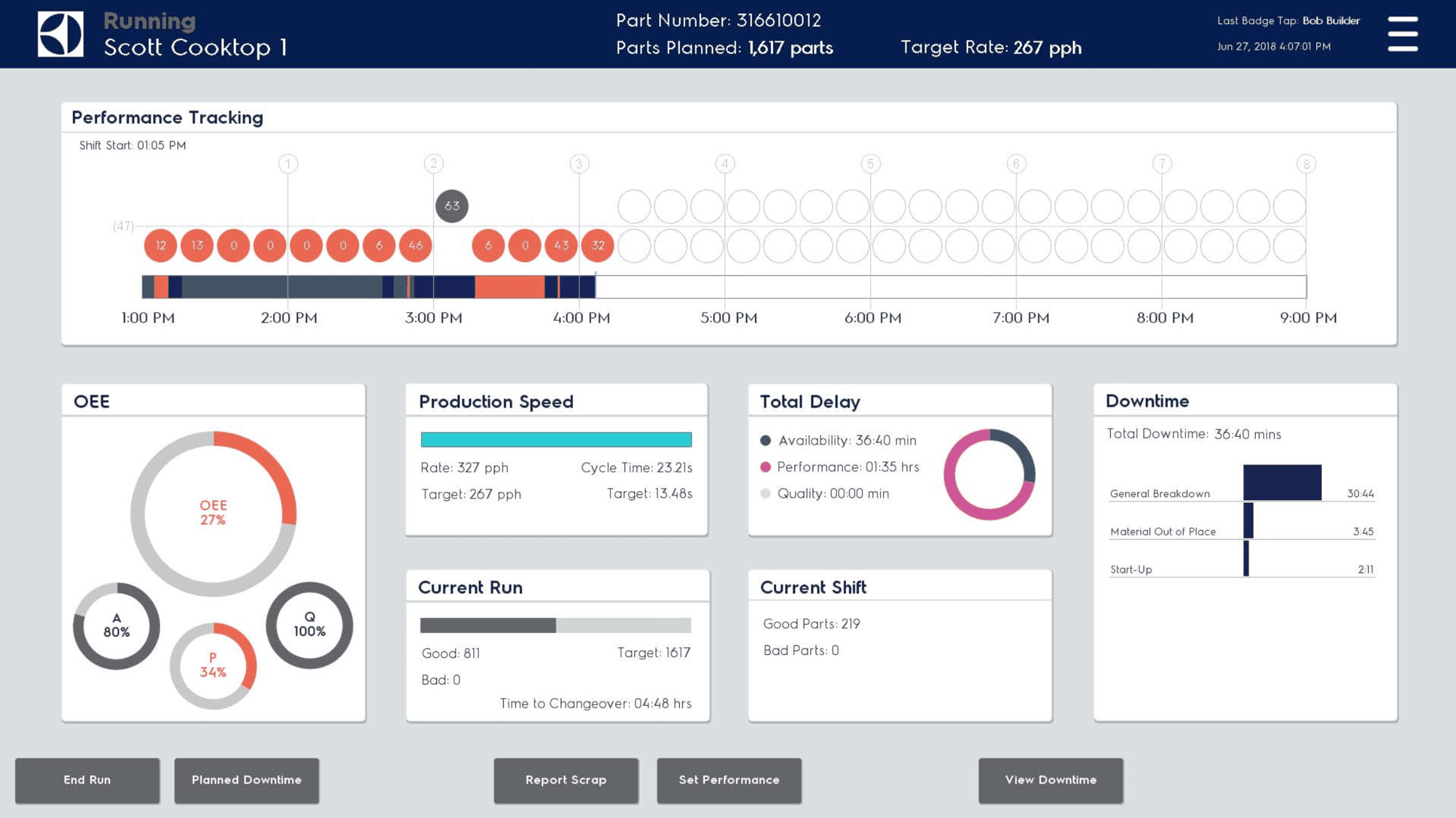

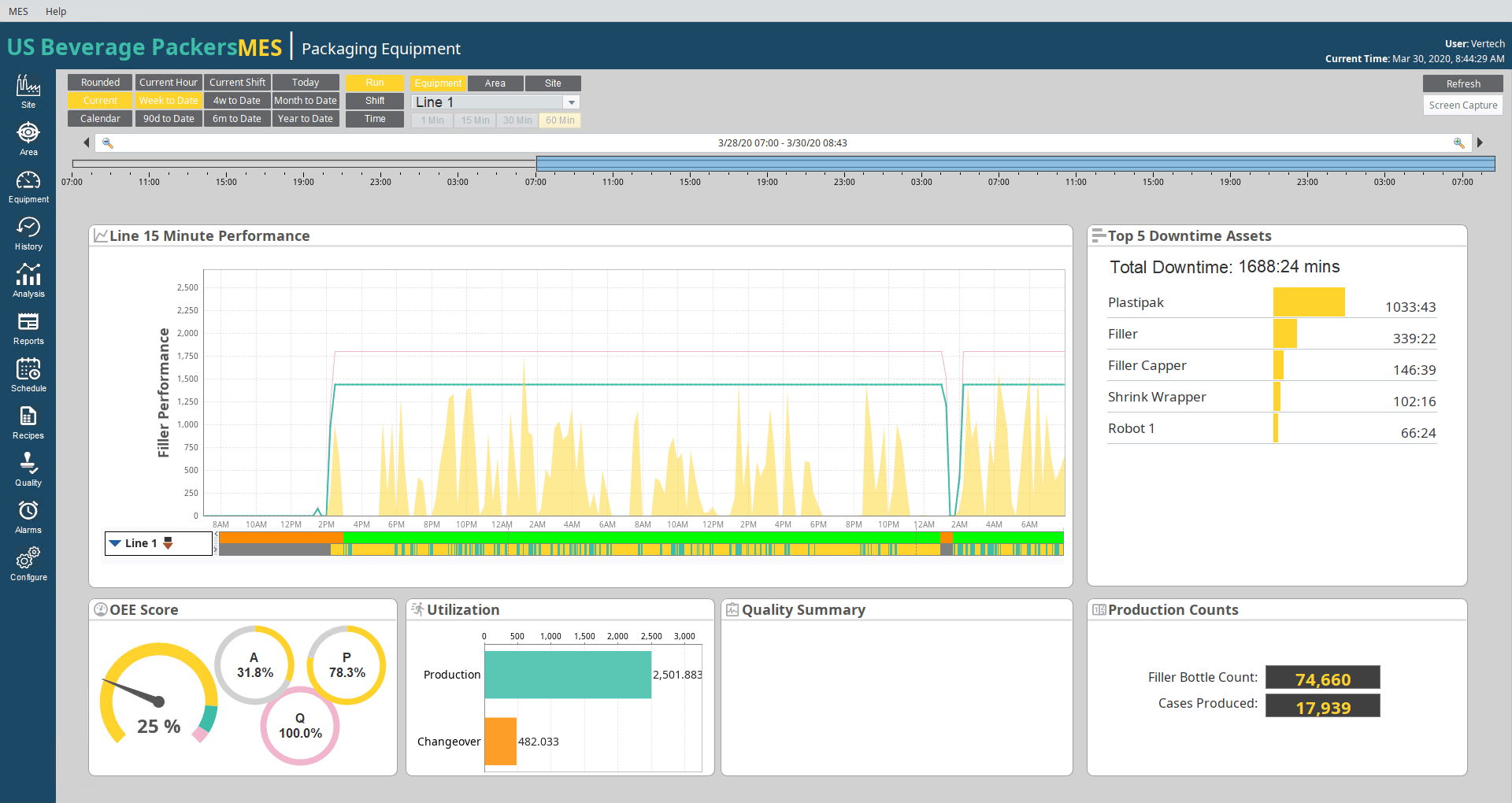

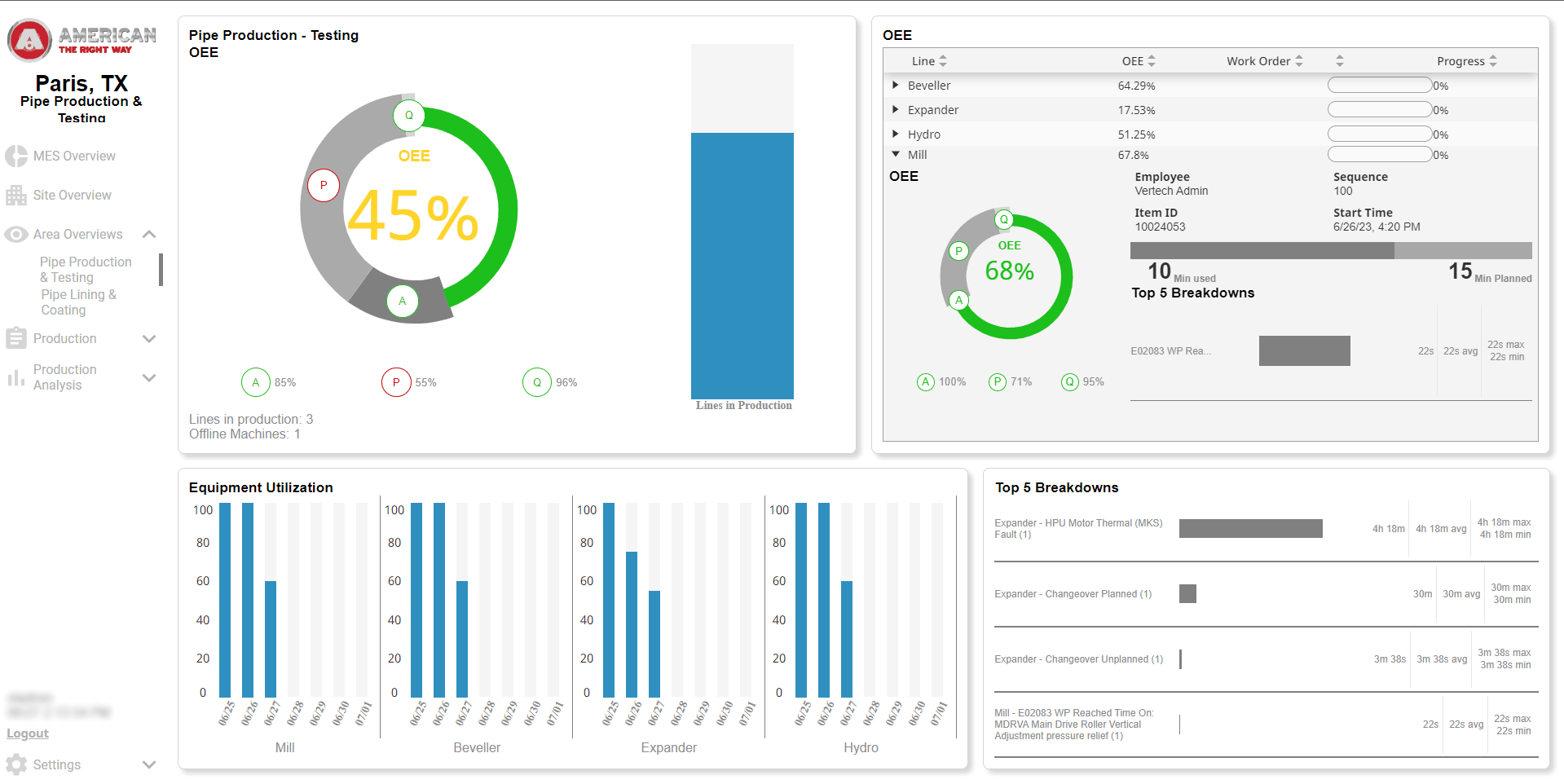

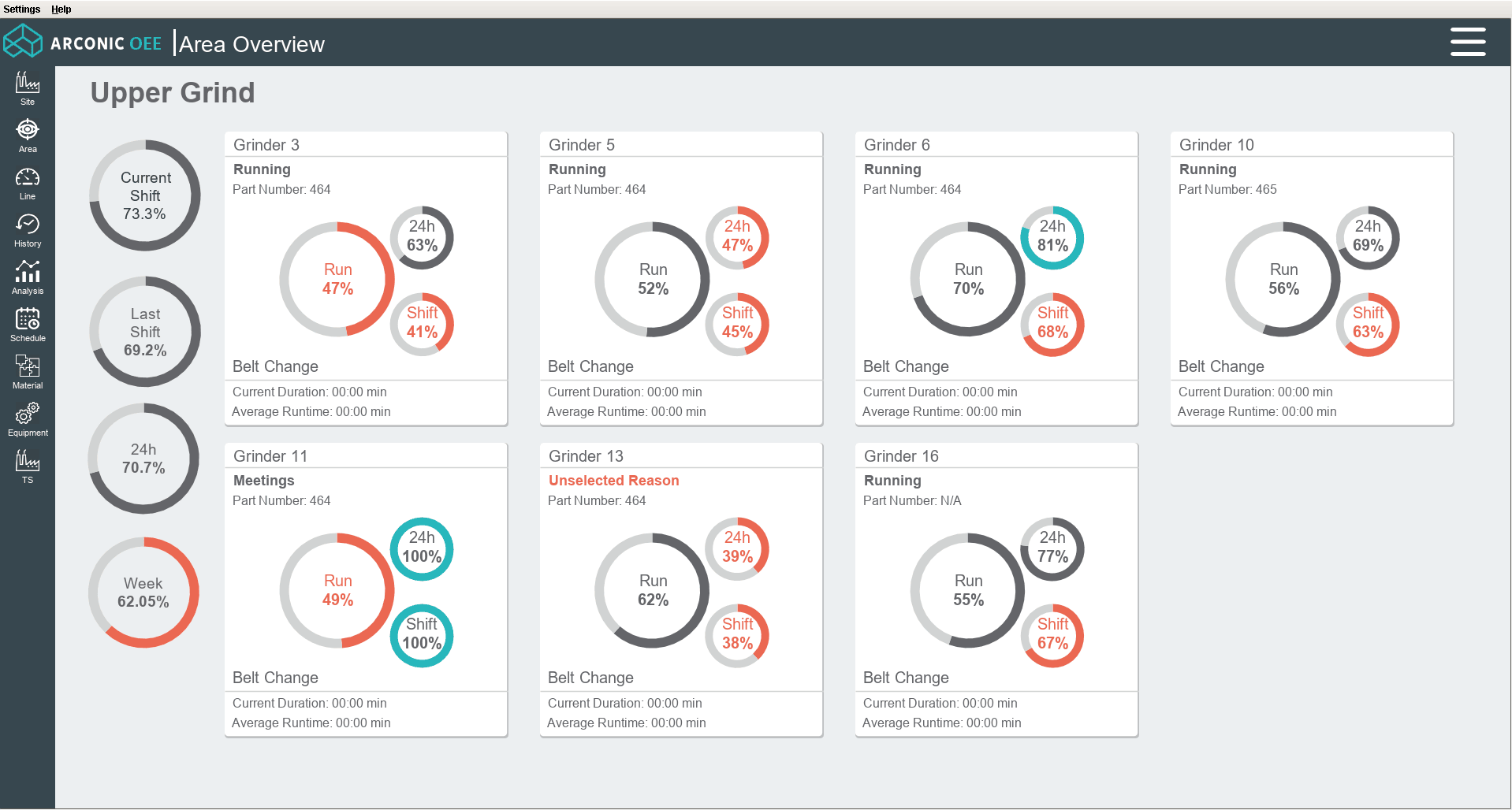

Efficiency & Overall Equipment Effectiveness (OEE)

Optimization requires more than just intuition. With our solutions, you can track quality, efficiency, and production rate and easily identify where your performance can improve.

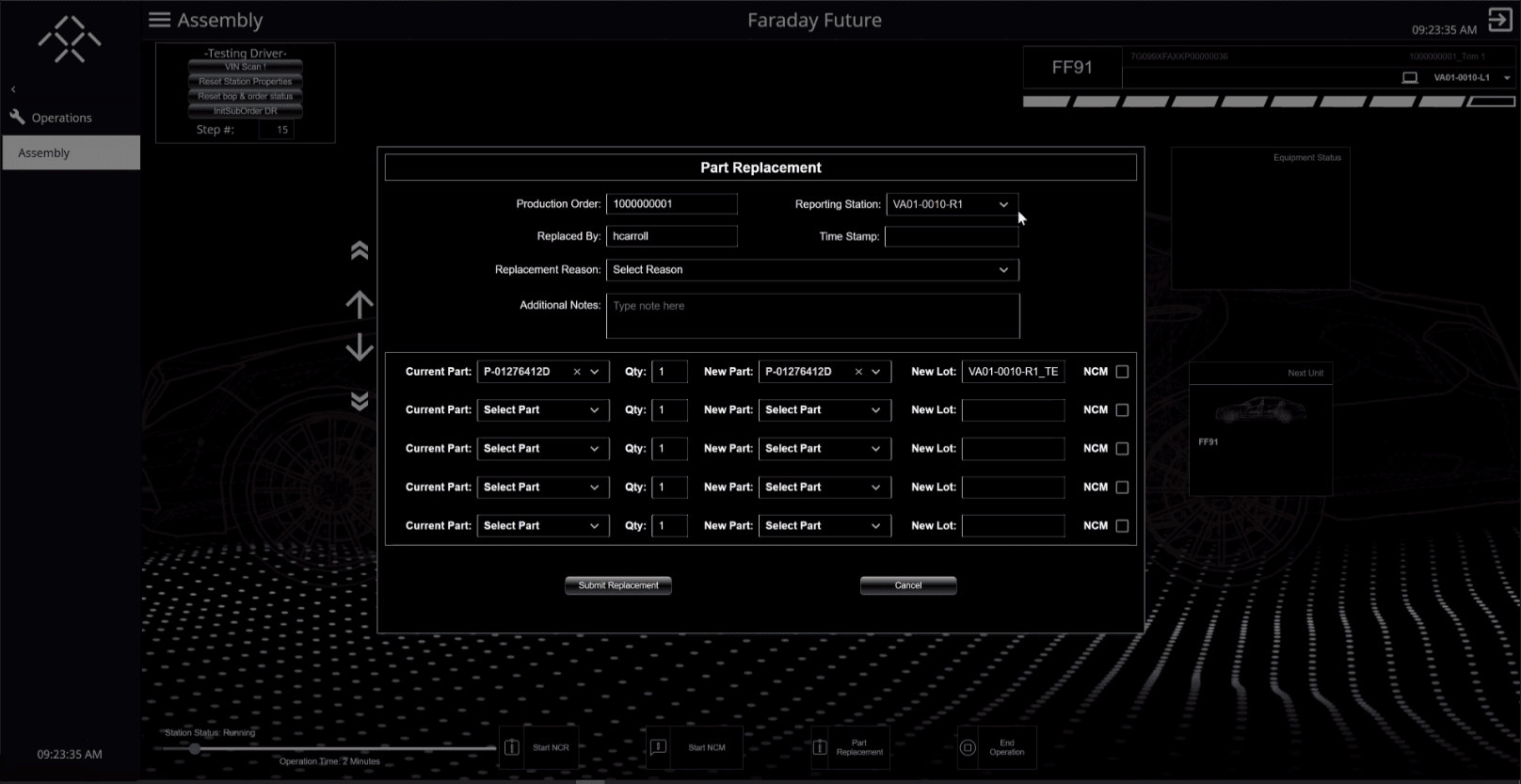

Production Tracking

Our track and trace solutions enable you to easily monitor lots and volume throughout your supply chain, ensuring that you have complete visibility at every step of the production process.

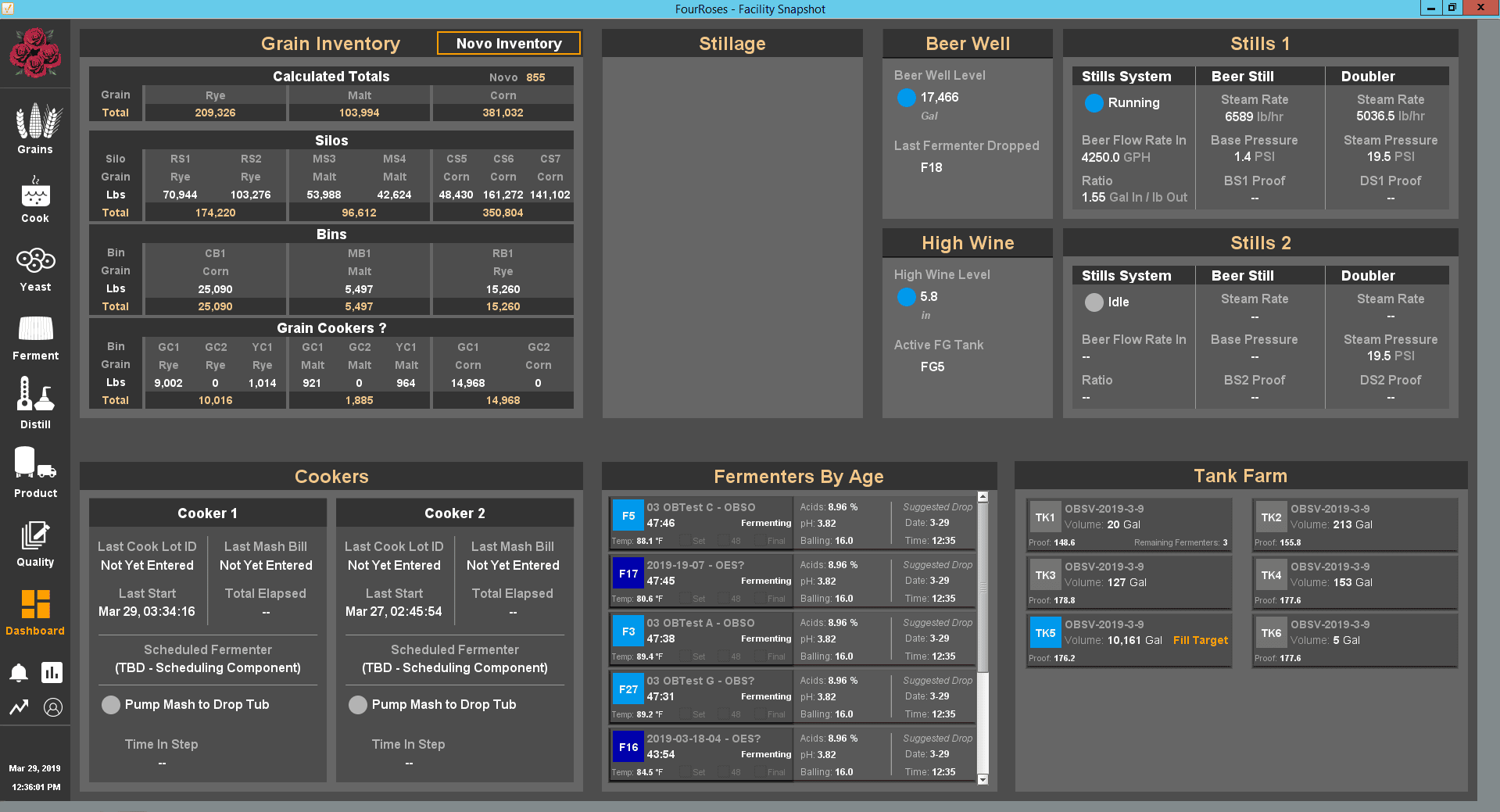

Batching & Recipe Management

Manage your secret formula with our secret formula: solutions that allow you to maintain your recipes in one central location, manage version control and vessel occupancy, and enable automatic continuous batching.

Plant Data

Excel records are so last century. Step into the present with real-time measurements and data stored in one central location for an accurate, up-to-date view of your production.

ERP Integration

Ready to streamline operations across your entire manufacturing lifecycle? Whatever ERP system you use, we’ll find a secure and efficient method for integrating information flow.

Some Companies We’ve Worked With

.png?width=117&height=80&name=arizona-tea-font%20(transparent%20background).png)

Real-World Success Stories

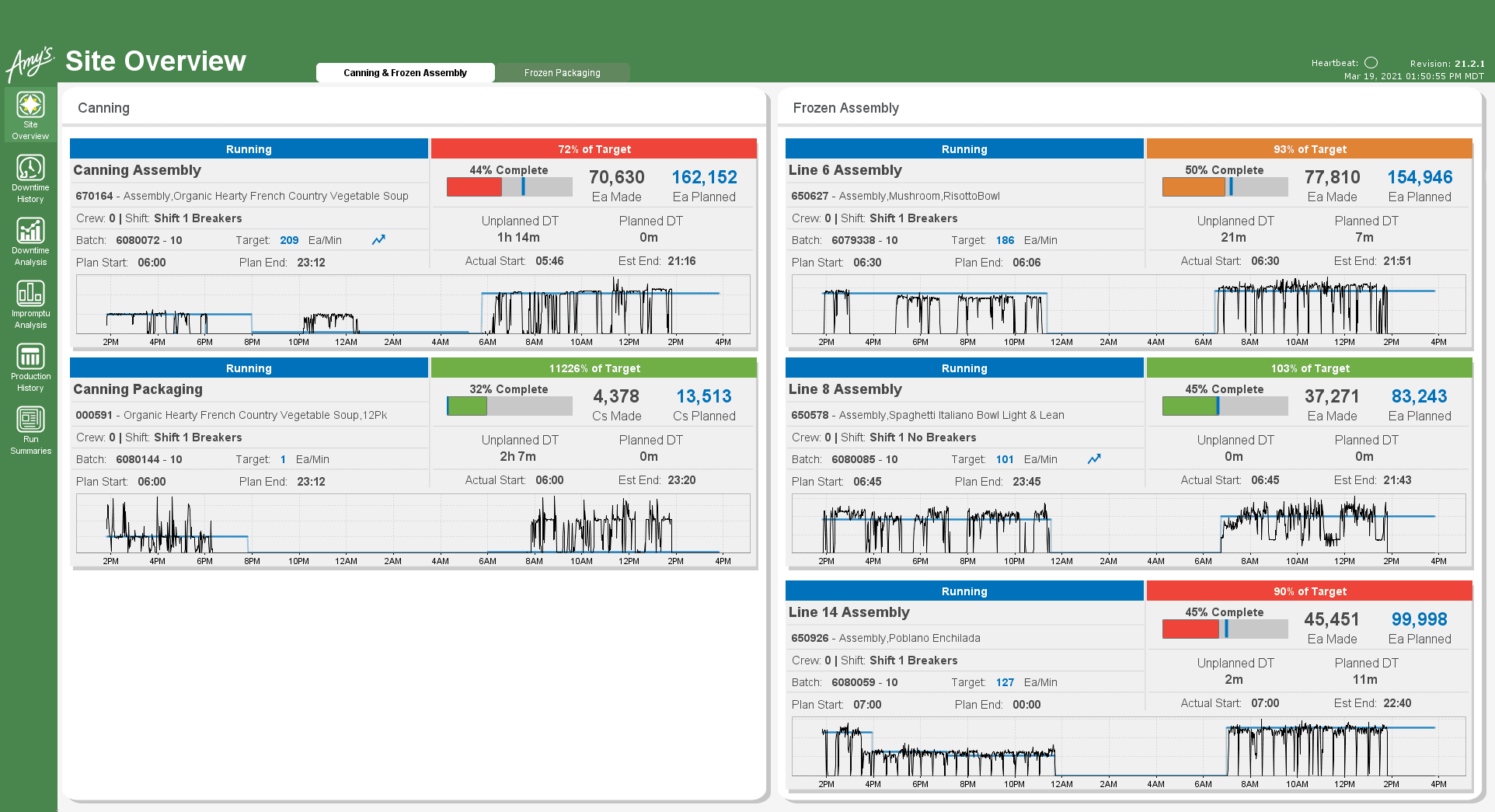

Amy’s Kitchen replaced their high-cost software with an improved OEE solution that fit their exact process and provided flexibility for future growth.

"Real-time data is absolutely essential. We have limited storage space. As soon as a product is made, it needs to be shipped to another facility. But, before we make each product, we have to create a batch. So we are basically doing just-in-time batching, which would not be possible without a system like this that can manage inventory and manage packaging goods"

"I am impressed with how easy it is to use. And I'm impressed with just how consistent it is. By giving us a view into what's going on and a way to look back at prior performance, we can gauge whether process changes or continuous improvement projects are really panning out."

"The operator screens enabled our operators and supervisors to get a quick idea at a glance of generally how the run is going and if you are on track to finish production on time. From the manager screens, I was able to keep an eye on things from my office and see if there is a problem that is going on so I can make needed changes."

Explore More Solutions

Why Vertech?

Successful MES projects require a team approach.

Using a collaborative, hands-on process, we work closely with your team to deliver a solution that improves your operations and benefits your people. We focus on delivering measurable value quickly and fine-tuning the solution based on practical feedback from the experts: you.

And at the end of the day, we stand behind our results. A fully connected plant floor means you’ll be able to make better decisions with real-time data and analytics straight from the source. In other words, our MES solutions just work.

Transform Your Manufacturing Operations

Want to know more about our MES solutions? Send us a message.

FAQs

What are the most essential MES tools for plant productivity?

We recommend implementing the following MES tools:

- Overall Equipment Effectiveness (OEE)

- Downtime Tracking

- Data Entry Automation

- Track & Trace

- Asset Management

- Predictive Maintenance

- Production Scheduling

- Recipe Management

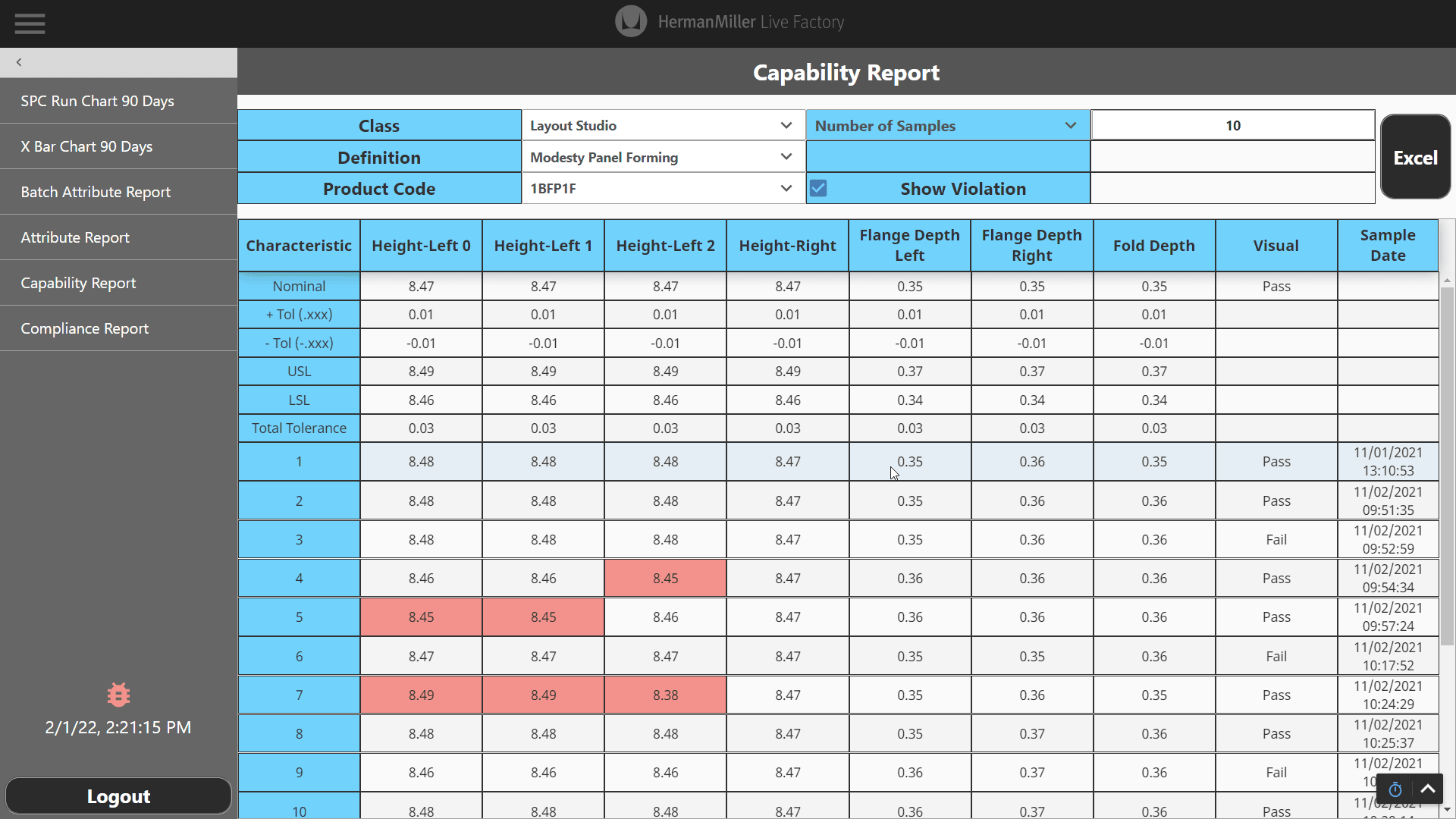

- Statistical Process Control

For a deep dive into each of these tools and how they can improve performance, download our white paper, 9 MES Tools Every Plant Manager Needs.

How can I ensure a successful MES implementation?

What should I consider when selecting an OEE solution?

How can I eliminate islands of information in my plant?

What are the first steps to becoming a fully digital factory?

What should I watch out for when applying big data analytics on the plant floor?

To extrapolate and interpret valuable data, use the four main pillars of data analytics to address the following key questions:

- Descriptive analytics – What has happened?

- Diagnostic analytics – Why did it happen?

- Predictive analytics – What is likely to happen?

- Prescriptive analytics – How can we make it happen and what are the consequences?

Related Reading

.png?width=750&height=679&name=247Support%201(1).png)

Introducing Momentum Method: Accelerating ROI in Digital Transformation

We are excited to announce the launch of Momentum Method, our human-centered process for building industrial software fast. Digital Plant Director, ...

Digital Plant Demystified: Facts & Fiction behind OEE, MES and More

Industrial Automation terms like Digital Plant, Digital Transformation, and MES get tossed around so much that I fear they are losing their meaning ...

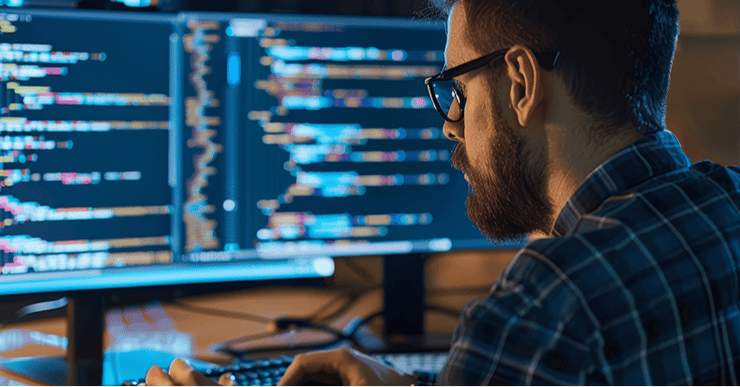

Why Unit Testing Matters in OT (and How to Do It Right)

Stop me if you've heard this one. An auto mechanic is talking to a heart surgeon: We do pretty much the same job. I open the car hood, you open the ...