Batch Control: The Secret Ingredient to Your Success

Want to introduce new recipes or procedures without the hassle of additional programming?

Batch control provides unparalleled control and flexibility for your equipment. It allows you to run multiple recipes on the same machinery, all while maintaining consistency and quality.

With our batch control software, your R&D and quality departments can make changes to your process anytime, without additional coding or outside support.

Explore More Solutions

Why We Batch

What Is Batch Control?

Batch control turns raw inputs (ingredients) into a valuable output (product) by moving them through an ordered set of operations. A big part of batch control is working within constraints like available labor, machine capacity, mechanical design, and quality requirements.

An easy analogy is baking cookies at home. You have the equipment and flexibility to make almost any kind of cookie, but to be successful, you need a list of ingredients, amounts, and a procedure (normal people call it a recipe).

The constraints of your kitchen equipment (how much dough your mixer can hold and how many trays can fit in your oven, for example) will determine how many cookies you can make at any given time and how many batches you’ll have to process.

The same applies to manufacturing — almost all processes have a starting point, a finite amount of processing time, and an ending point, which makes them batch processes. For each procedure, your equipment must manage raw input quantities, temperature, pressure, etc., and perform all steps in the proper sequence.

Batch control allows you to seamlessly adjust existing recipes and move between different procedures without disrupting the entire manufacturing process or impacting quality — and without the hassle of additional controls programming or the need for extra support.

What Is ISA-88?

The S88 standard, also known as ANSI/ISA-88 or Batch Control, is a crucial component in industrial automation. Created by the International Society of Automation (ISA), this standard focuses primarily on the plant floor SCADA layer and provides a structured method for implementing and maintaining batch processes.

ISA-88 acts as an extension of ISA-95, facilitating the transfer and influence of master formulations and recipes from the ERP and MES layers down to the batch control recipes found in ISA-88. As batches are produced, materials used are often tracked and reported back up to MES and ERP layers for inventory control, traceability, and electronic batch reporting.

.png?width=954&height=954&name=batch-services(1).png)

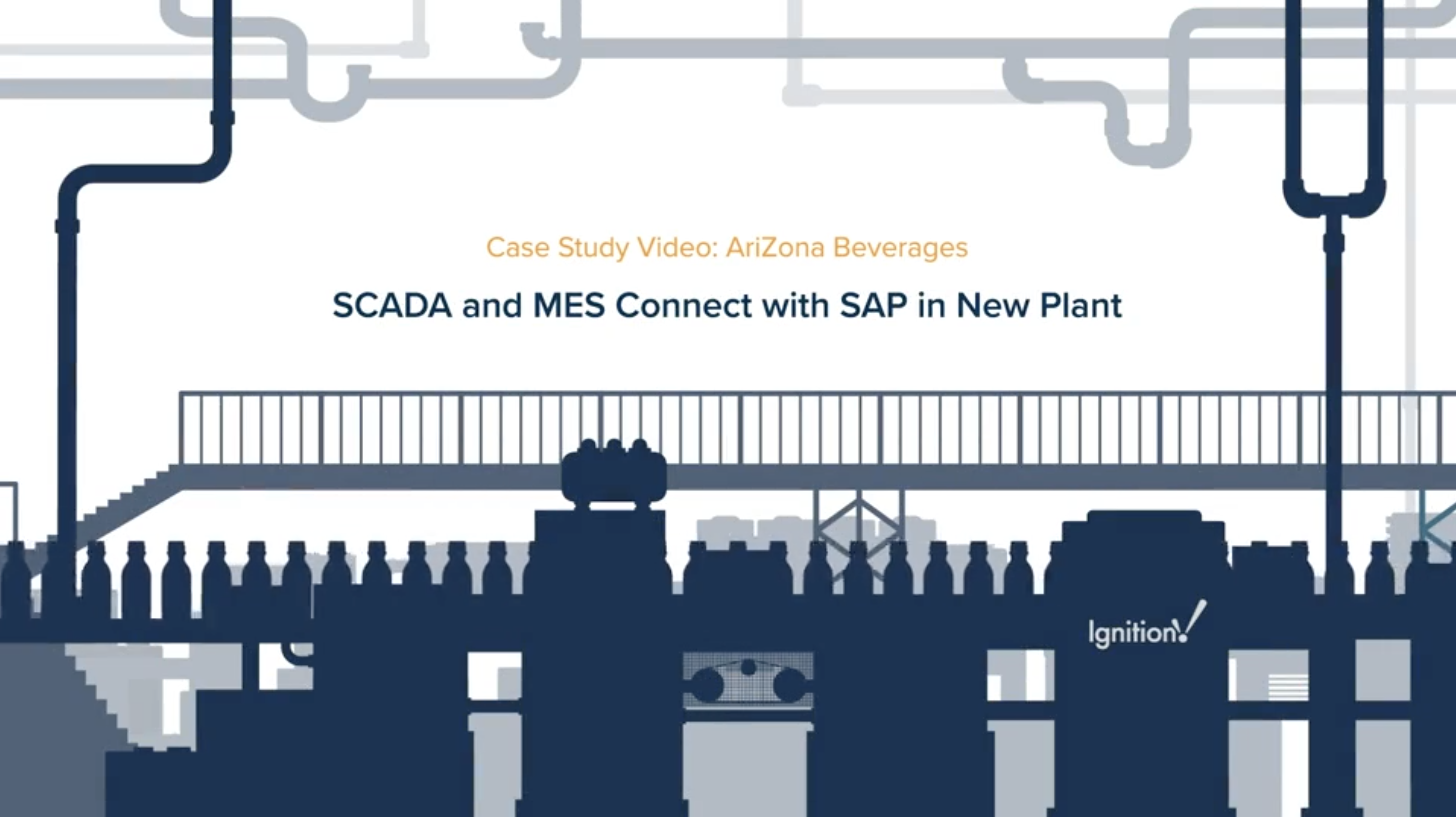

Batch Control at AriZona Beverages

“Real-time data is absolutely essential. We have limited storage space. As soon as a product is made, it needs to be shipped to another facility. But, before we make each product, we have to create a batch. So we are basically doing just-in-time batching, which would not be possible without a system like this that can manage inventory and manage packaging goods."

Explore More Solutions

Digital Plant Services

Digital Plant Services

Digital Plant Services

Digital Plant Services

Our Technology Toolkit

Why Vertech?

.png?width=953&height=953&name=vertech-batch(1).png)

We bring tangible value to the people we work with by providing operator-friendly, bulletproof software and automation tools for your industrial operations.

With a ton of experience in Ignition, Rockwell, PLC programming, and more, we hope to make plant operations a little easier by delivering systems we're proud of, treating people with respect, and having a little fun along the way.