Automotive Manufacturing Automation

Driving Innovation in Automotive Manufacturing

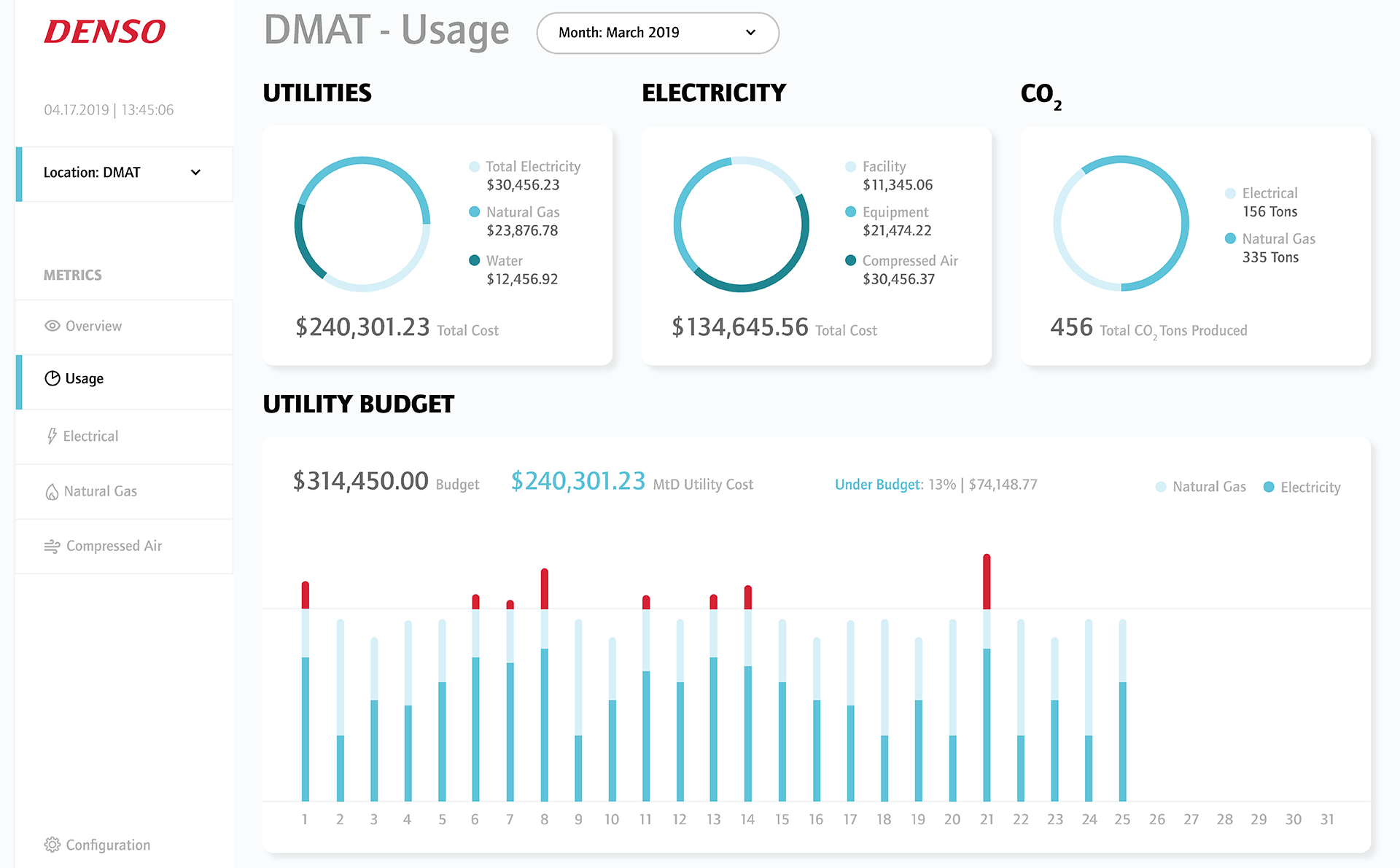

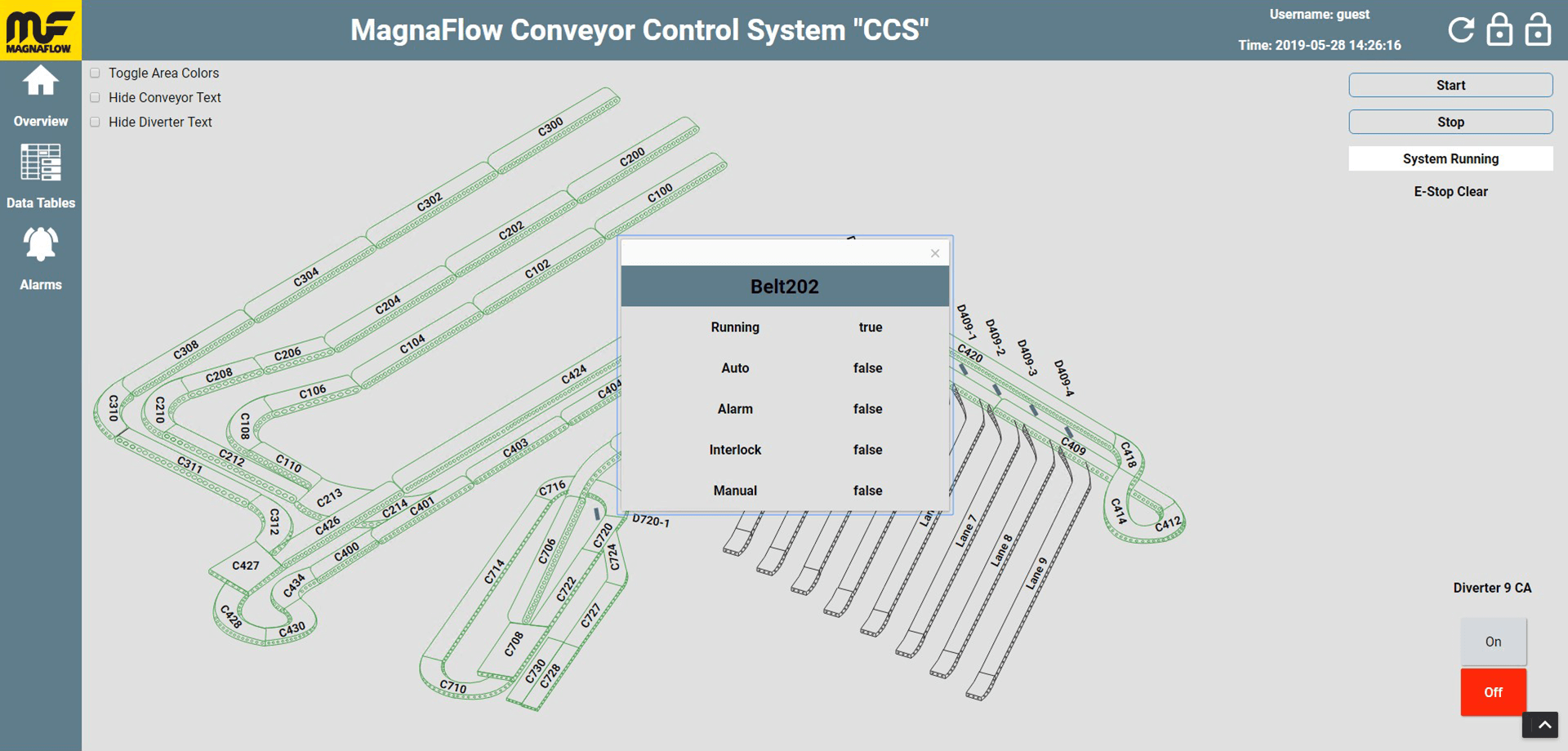

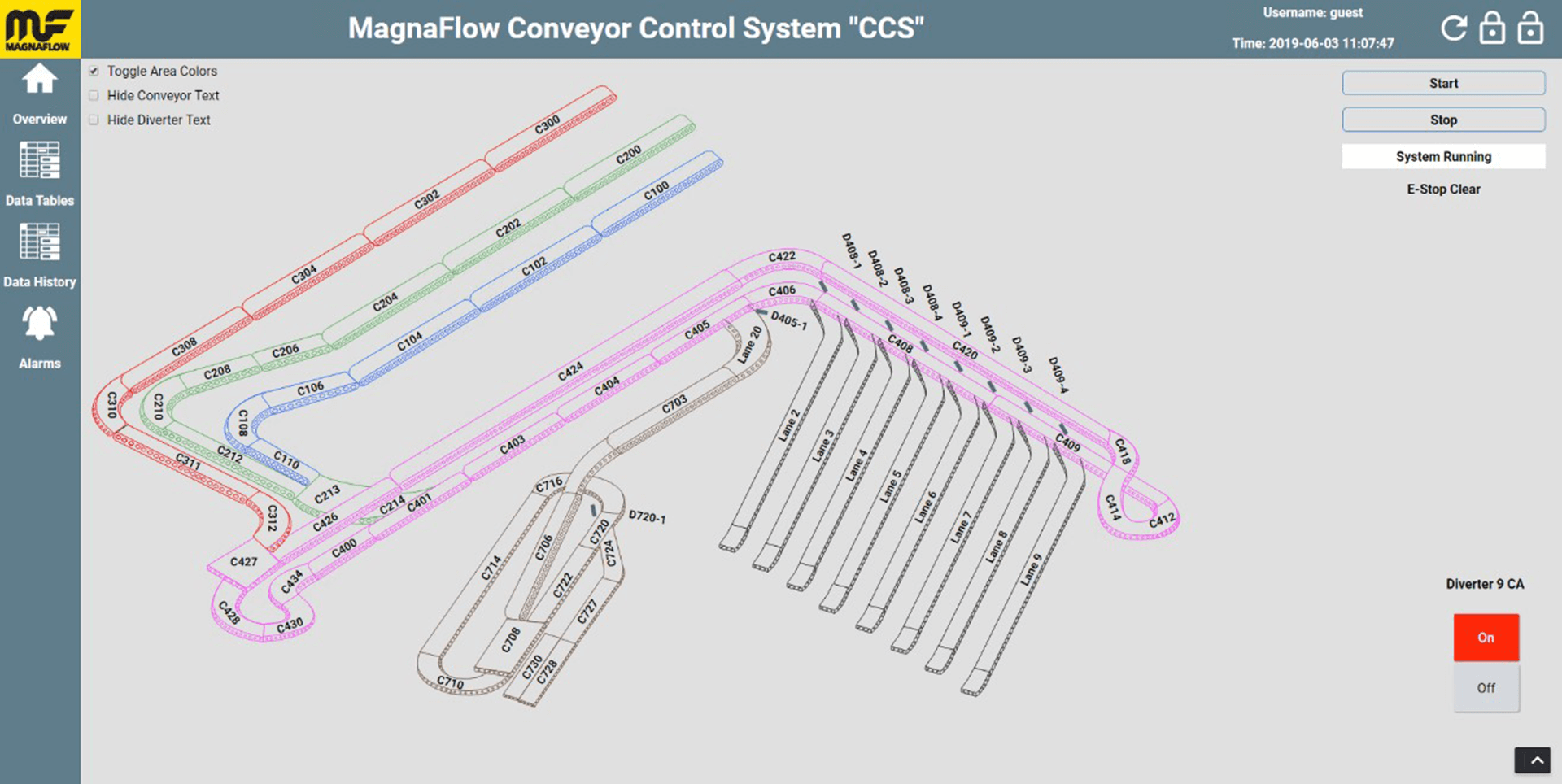

Your automated assembly lines should hum like a finely tuned engine. If you're grappling with data silos, solving 2:00 AM emergencies, and contending with clunky interfaces, it's high time for an overhaul.

Your manufacturing software should fit your operations, not the other way around. What if you could have seamless data communication with existing software, precise order tracking and quality control, and a live feed of your entire operation in one place?

With you in the driver’s seat, we’ll engineer a system that not only works but isn’t a headache to use. From PLC controls to SCADA and MES solutions, we design and program systems that connect your data and give you total control.

(1).png?width=1294&height=988&name=VER_Automotive_Screenshots(2)(1).png)

We know Automotive Manufacturing…

...and we know Ignition.

Make your screens top-tier.

Automotive Automation Solutions that Put You Behind the Wheel

Manufacturing Execution Systems (MES)

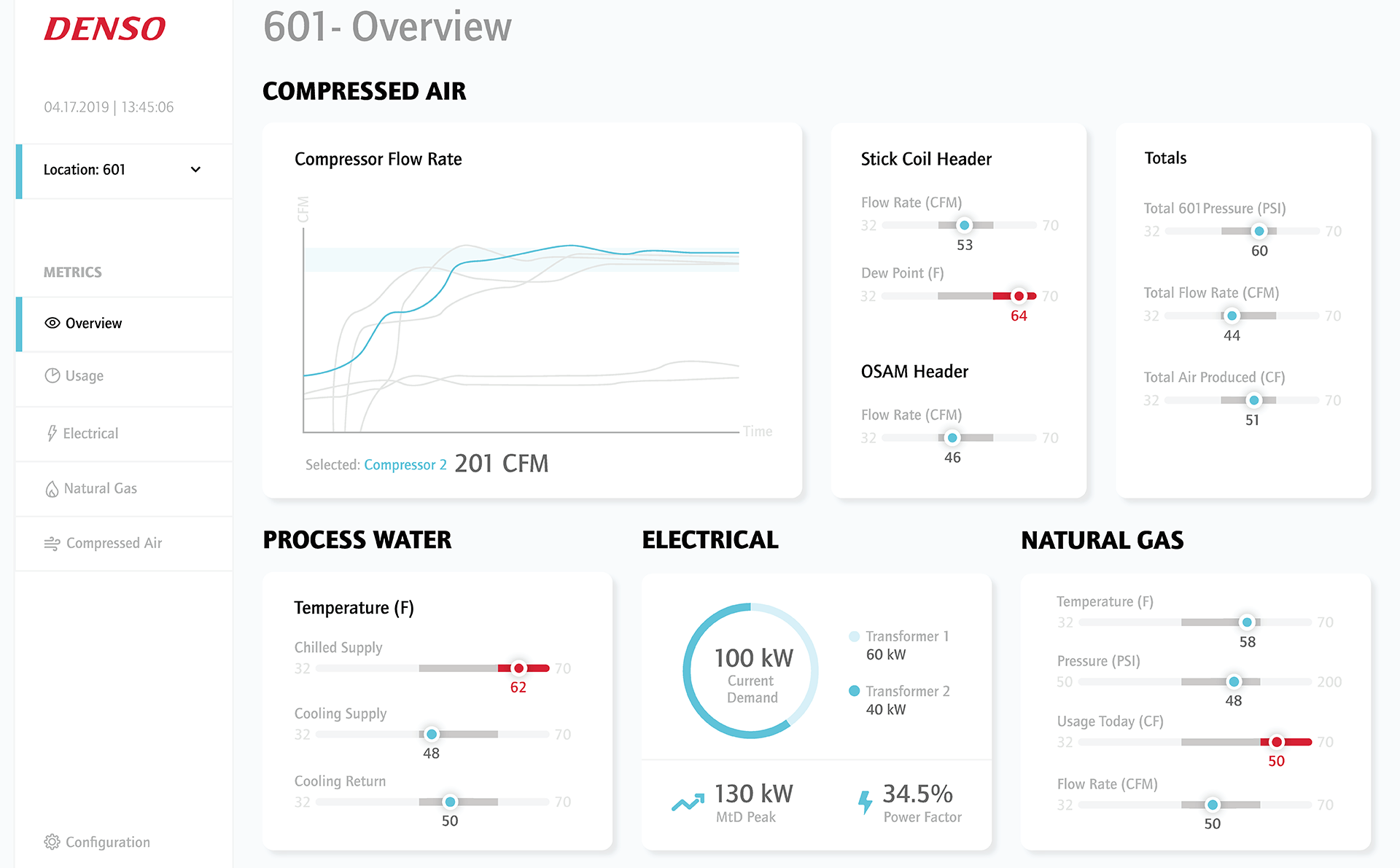

Grease the wheels of your complex manufacturing process with our optimized MES systems. Get better visibility from line status and OEE to scheduling and inventory, ensuring seamless coordination across your plant. Maximize efficiency and resource utilization while minimizing waste.Process Automation (SCADA)

Get real-time control over your manufacturing processes and ensure total visibility into the status of all your equipment. Drive time-saving processes like automatic ticket maintenance.Control Systems

Modernize your hardware, software, and network infrastructure with custom control systems, PLC and HMI/SCADA programming, control panel design, and more to build a solid foundation for your MES system and maximize the long-term return on your investment.Some Companies We’ve Worked With

All About Automotive MES

Track & Trace

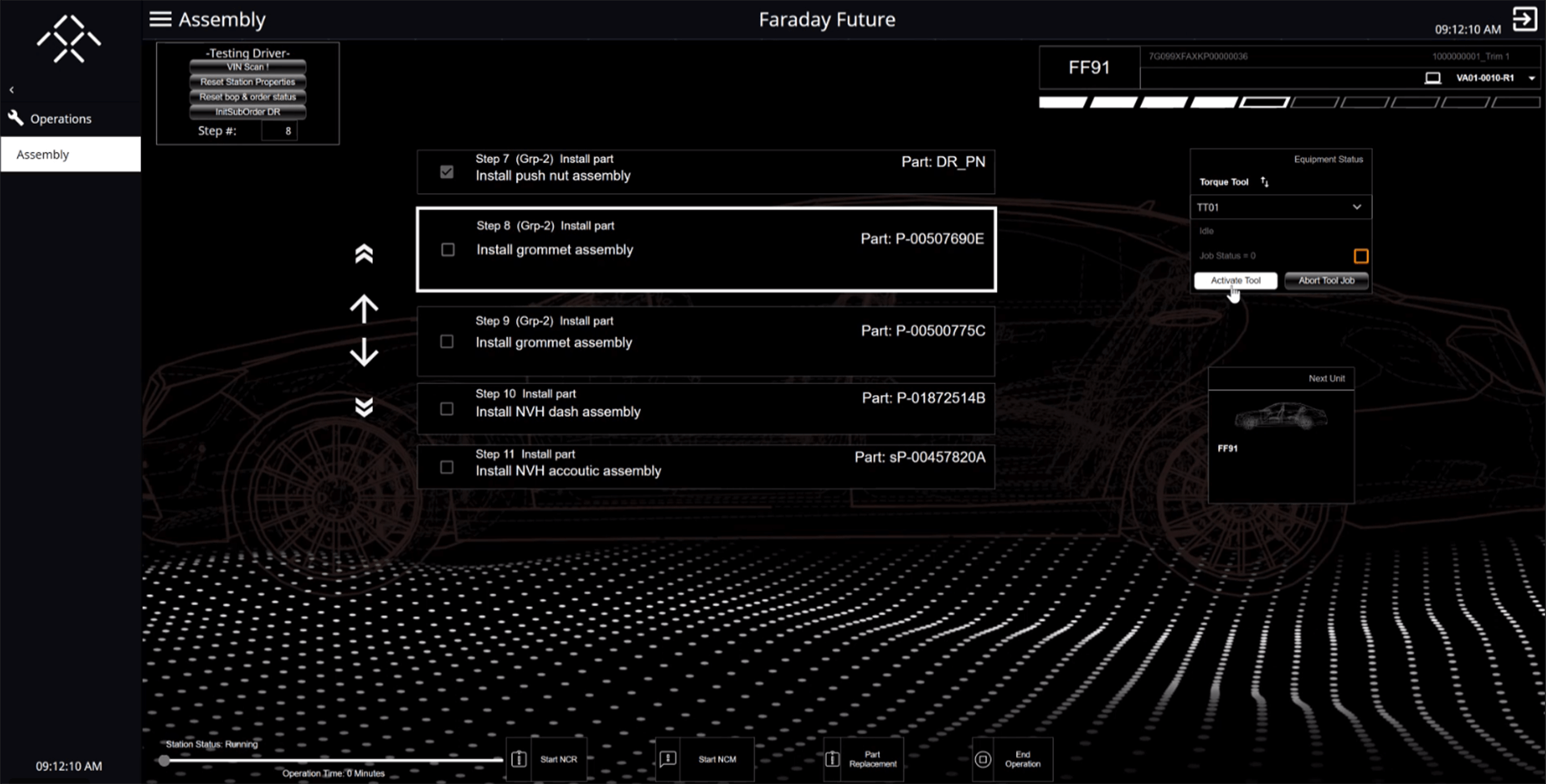

Stay above the standard with accurate part tracking and serialization. Capture data on mission-critical parts with seamless Critical Component Traceability.Poka-Yoke & Validation Tracking

Automate rigorous process analysis tools that ensure successful process completion and flag defects immediately.Bill-of-Process (BOP) Management

Our custom BOP systems specify what steps should be taken at every station on the factory floor, and who should take those steps — robot, machine, or human.Paperless Orders

Whether it’s a production order, work order, planned order, or beyond, track the steps of the BOP throughout the facility. This integrates as a critical part of many of the other MES features.Digital SOPs

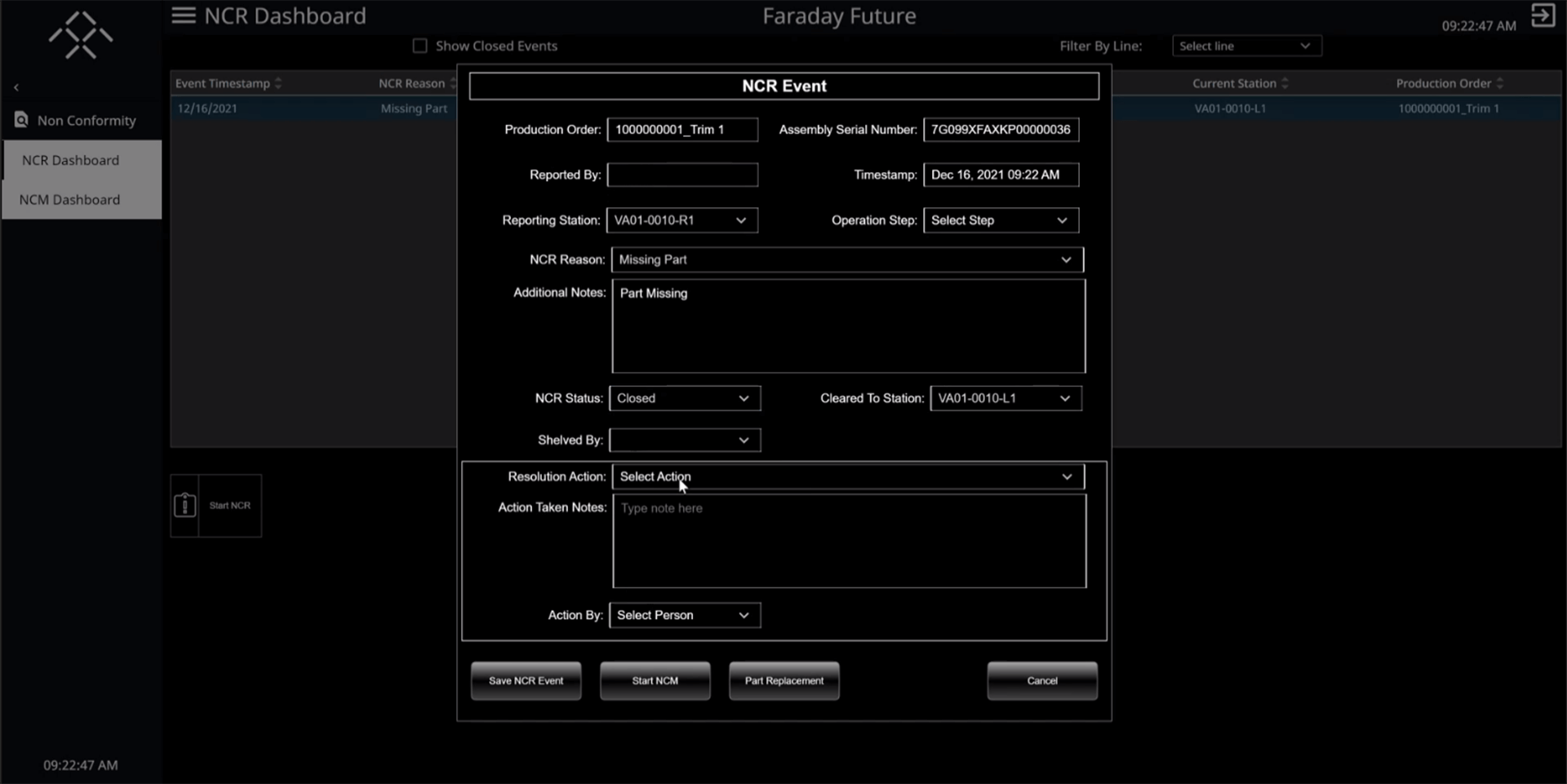

Provide operators with digital SOPs based on contextual situations (current unit, process, step, part number, etc.). This feature can be easily combined with paperless orders to make things even easier.Defect & Repair Tracking

Easily track any defects that occur on the line, then dispatch and track repairs for those defective parts.Support Requests & Dispatching

Enable operators to request support from various teams (e.g. Material Handling, Maintenance, Quality) and build priority queues for each group to respond to requests. View support metrics, KPIs, and reporting.Maintenance Management Integration

Get alerts when machines need attention. Manage machine maintenance with runtime hour tracking, auto-ticket generation, and ticket escalation.Line Balance & Takt Timing

View trends and analysis with comprehensive time tracking at each station.Order & Unit Sequencing

Manage the sequence of orders from your ERP before they hit the production floor, and compensate in real time for changes in sequencing due to rework or skipped units.Kitting

Create “orders” for kits of parts to be gathered on a sub-assembly line. This feature integrates with Order and Unit Sequencing and Paperless Orders.WIP Tracking

Know exactly how much inventory you have on each line. This integrates well with features like Support Requests and Paperless Orders.Why Vertech?

(1).png?width=477&height=477&name=Photo(3)(1).png)

We get you. We have extensive automotive experience and have built some beautiful automation for state-of-the-art manufacturing plants. We're familiar with the complex processes that need to work together to get the job done well AND capture data at each step.

Not only are we a quick study on your specific process, we're also #1 in Ignition, the leading industrial automation software. (But somehow we still can't make a good cup of coffee in the office.)

So give us a call. We've got your back.

.png?width=115&height=100&name=IA-Premier-Integrator-MES-lg(1).png)

Ready to take control?

Rev up your plant with a top-notch solution in Ignition. Send us a message!

White Paper

9 MES Tools Every Plant Manager Needs

Imagine having all your plant's data at your fingertips, accessible to everyone who needs it. That's the power of Manufacturing Execution Systems (MES)...