5D Process

Project Execution Wizardry

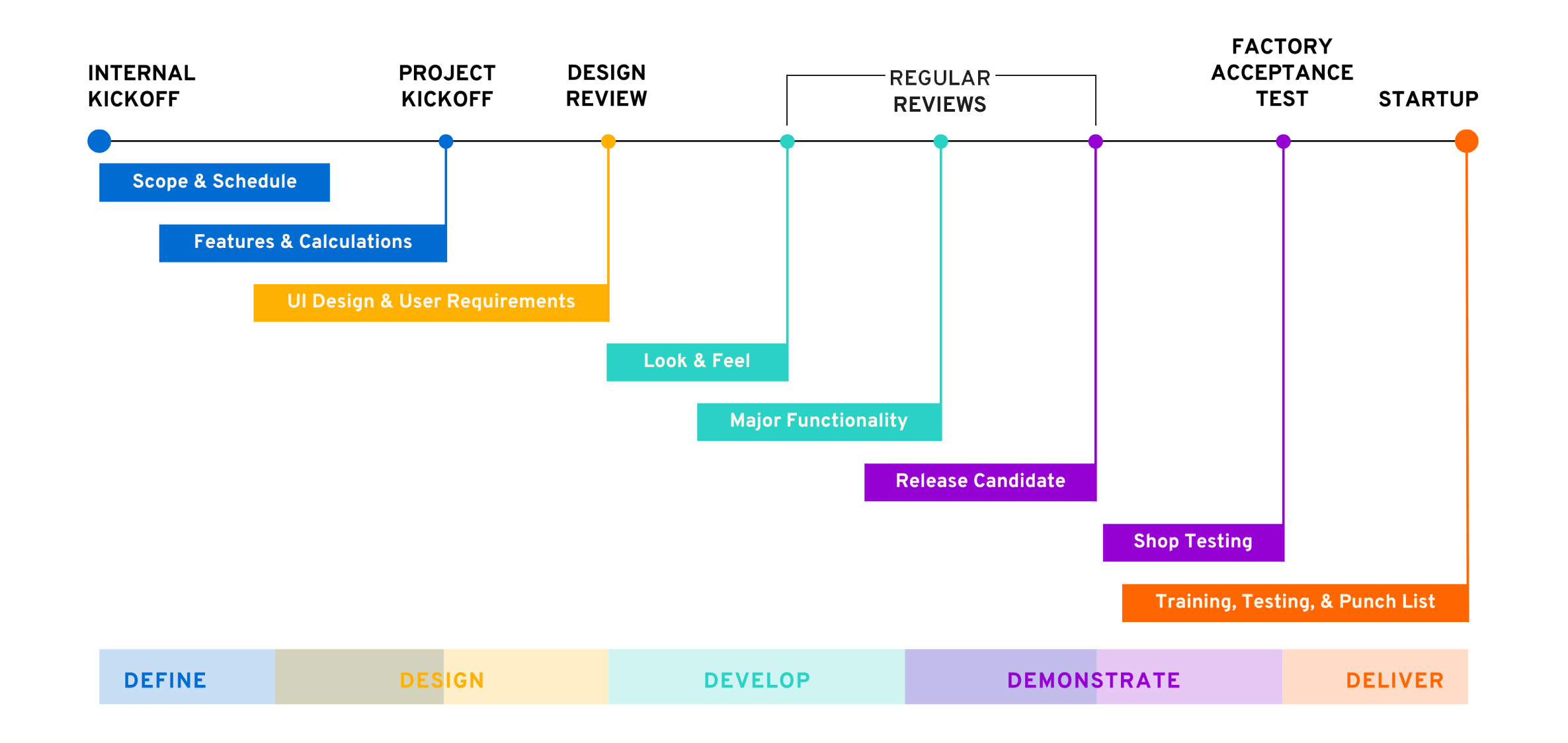

To say industrial automation projects can be complex is an understatement. That’s why we simplified our project execution into five steps we call our 5D Process: Define, Design, Develop, Demonstrate, and Deliver.

Think of us as your guiding Tech Wizard. Our engineers take you on a journey to determine the most effective approach, define machine functionality in detail, and deliver a reliable, user-friendly automation system that’s customized to your needs.

Define

First, our team huddles up to assess the Scope & Schedule. Then, we meet with you at your site and delve into our Features & Calculations documentation.

This way, we start our journey together with a deep understanding of the objectives, expectations, and requirements.

Design

With our team and route set, it’s time to select the tools and supplies we’ll need along our journey.

We start by gathering your criteria in our UI Design & User Requirements document. It's a collaborative process, where your specifications are listened to and incorporated.

Then, we design a system tailored to your goals, providing network drawings, data maps, UX/UI concepts, and features for every screen.

Develop

Now, it’s time to set out on our quest, navigating unknown terrain and braving challenges together.

We review the Look & Feel of the project, ensuring the overview and major navigation align with your vision.

And we delve deeper into Major Functionality, adjusting our course and strategy as needed.

As your expert guide, we ensure that every step we take aligns perfectly with your vision and leads towards your project's success.

Demonstrate

As we approach our destination, we demonstrate our solution’s toughness and resilience by conquering any final obstacles to product launch.

We Release the Candidate and put our software through rigorous Shop Testing as we demonstrate the system forged through our shared efforts.

You’ll join us in workshops and participate in the deployment process. We meticulously review the system performance and functionalities, ensuring all panels, PLC programs, and HMI/SCADA run smoothly and satisfactorily.

Deliver

But rest assured, our partnership doesn't end here. We‘ll be there to provide long-term support, guidance and maintenance for your new automation system.

Your Long-Term Ally

We're with you for the long haul, providing the support you need to keep your industrial automation systems operating smoothly year after year.

Our expert team of engineers can resolve system errors and keep everything up to date. MES and SCADA systems are our bread and butter, so you bet we know how to fix them!

- System backups

- Security and industrial IT updates

- Document control

- Annual visit and system review

- Regular reports

- Emergency system recovery

- Production errors

- Data errors

- Security patches

- Connectivity issues

Make your problem our problem. We’ve got your back!

.png?width=1200&height=942&name=support-hero(1).png)