According to the IDC market research firm, public cloud services and infrastructure are forecasted to become a $277 billion worldwide market by 2021, with discrete and process manufacturing as two of the top five industry consumers. Cloud computing is not just a passing trend. It’s a foundational technology that has the power to improve product quality, accelerate decision making, and cut costs – all scalable to your business’s needs.

But what does cloud technology mean for a manufacturing plant, and does it really make financial sense? Amazon Web Services (AWS) defines cloud computing as “the on-demand delivery of compute power, database storage, applications, and other IT resources through a cloud services platform via the internet with pay-as-you-go pricing.” A cloud-based system has the ability to grow incrementally with your business, allowing you to pay only for the infrastructure needed and scaling as you grow.

From better reliability and more readily available data to easier scalability and elasticity and integration, there are numerous benefits to incorporating cloud technology into your manufacturing floor.

Weighing the Benefits Versus Costs of the Cloud

For most manufacturing enterprises, there are a lot of cost savings that come with using cloud computing. There’s a low cost of entry, and you can reduce your corporate IT resources. You’re essentially trading the capital expense of owning your own data centers for a variable expense based on usage levels, thus mitigating financial risk. And from our experiences, the acquisition cost for software and hardware is only a fraction of the IT spend. The majority comes from the operating costs for the network, facilities, IT labor, maintenance, security, backups, management tools, power and cooling, and so on. By outsourcing some of the responsibility, you can focus more resources on new product designs, plant productivity, and quality assurance.

Numerous studies have analyzed the short- and long-term economics of cloud computing. As stated in The Economic Benefit of Cloud Computing, “a cloud computing approach could save 50 to 67 percent on the lifecycle cost for a 1,000 server deployment… [delivering] greater investment returns in a shorter payback period when compared to the traditional on-premise delivery option.”

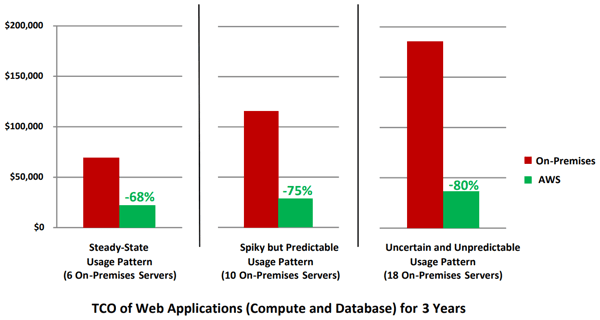

And according to AWS, the total cost of ownership (TCO) for cloud computing can offer up 80% cost savings over the equivalent on-premise option (see their chart below). AWS also offers an online TCO calculator as an additional cloud computing cost analysis resource to check out.

On one hand, depending on the amount of data in the enterprise, it may make more sense for huge corporations to have their own data centers because it would be cost prohibitive to regularly transfer so much data over the cloud. We once worked with an organization that had hundreds of terabytes to transfer, and it was cheaper and faster to use FedEx to ship the hard drives across the country than upload it via the Internet.

On the other hand, billion-dollar companies like Netflix are 100% cloud-based with massive amounts of streaming and storage, but they’ve found a way to make it cost-effective. As cloud technology continues to grow and storage costs lower, you’ll see more and more large enterprises moving to the cloud, so research the benefits and costs for your company.

Case Study: Central Service with Many Users

We’ve worked with many different industrial and manufacturing clients and have seen numerous cases where the cloud makes a lot of sense to implement. Some businesses are very cyclical and on-line services offered will have varying usage needs throughout the year.

Water management authorities, for example, sell water rights online to consumers every year. During the contract renewal month, the agency may have hundreds of thousands of users hitting their site. With a traditional IT approach, they would need to build infrastructure that would support that peak usage for the entire year and incur the associated cost all year long. With a cloud-based solution, the site can automatically scale up in response to the spike in demand during contract renewal month, and then scale back down to handle normal traffic for the rest of the year. As seen the previous chart, the cost savings can be as much as 75% in this environment.

What to learn more? Read the full whitepaper Demystifying the Cloud for Manufacturing that discusses the benefits, concerns, and practical use cases for cloud computing in the industrial world.

Comments