Wouldn’t it be nice if you had a crystal ball on your factory floor that would tell you exactly when a problem was about to happen? While, statistical process control (SPC) isn’t quite a crystal ball, when integrated as part of your organization’s quality assurance/quality control (QA/QC) process, it’s close.

A specialized form of data analytics, SPC software samples key production variables and compares those variables against known tolerances. In layman’s terms, this means SPC can give plant managers visibility into a possible problem, like a tool that is wearing out, before it turns into a big issue that causes downtime.

Since most companies have an entire QA/QC division with software to meet the specific needs of the organization, we recommend using SPC as an MES tool that ties into your existing software. As part of your QA process, SPC helps ensure your production is operating at its full potential, which means the process is producing as much conforming product as possible with a minimum amount of waste.

Beyond ensuring the efficiency of your operation, there are numerous benefits of integrating SPC as a part of your QC process. First, SPC emphasizes early detection and prevention of problems rather than correction of problems after they occur. Second, SPC software records sampled data for future analysis should a quality problem be caught later in the process, which provides valuable information to troubleshoot problems and improve systems.

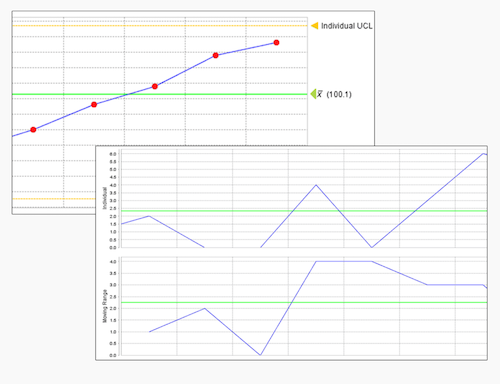

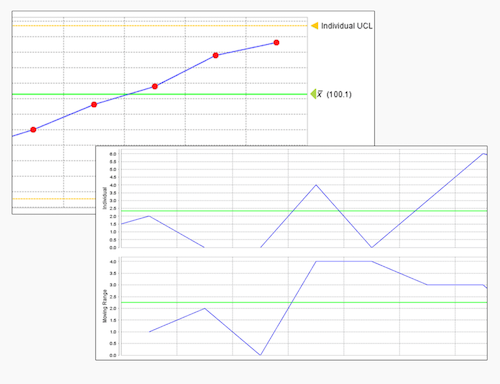

Third, SPC helps automate data gathering by pulling data directly from instrumentation and equipment so measurements can be taken with more frequency and accuracy. Finally, SPC data can be viewed in real-time by anyone in the facility who needs visibility into this information. Data delivery can be customized using flexible control charts and analysis tools.

SPC software provides more insightful data to help ensure production quality

With a strong background in industrial control systems, our MES team will work with you to develop a data collection strategy and implement off-the-shelf SPC software in your production environment. This will allow your company to easily continue using you preferred QA/QC software, but with our data—essentially creating a more robust QA/QC process.

Download our 9 MES Tools Every Plant Manager Needs to Improve Business Performance white paper to examine all the best MES tools for increasing business performance.

Comments