CASE STUDY

Georgia Power

30 Megawatts of Solar Energy Built on SCADA

Enterprise SCADA Streamlines Processes for Renewable Energy

The Protagonist

Georgia Power is the leading electric utility in Georgia, USA, providing upwards of 88.4 billion kilowatt-hours of power per year to its 2.7 million residential, commercial and industrial customers.

They are dedicated to providing reliable and affordable electricity across the state of Georgia and play a pivotal role in supporting the state's growth by investing in charities and sustainable energy projects, including solar power and smart grid advancements.

The Story

The Challenge

Integrate a full spectrum of utility-grade photovoltaic power generation equipment into a single SCADA system.

Georgia Power embarked on a mission to construct a power plant-scale solar field, which required the integration of diverse utility-grade photovoltaic power generation equipment into a single SCADA system. This included inverters, trackers, soiling monitoring stations, meteorological stations, substation power meters, and relays. The team at Georgia Power also required technology that their maintenance and operations groups would be familiar with to ensure long-term operational support.

The System

Build a SCADA system with an intuitive interface to monitor and control equipment from various manufacturers in one graphical environment.

Vertech implemented a full Allen-Bradley / Rockwell Software package, including a CompactLogix PLC acting as the plant master controller, Micro series PLCs acting as local data concentrators, a distributed FactoryTalk View SE HMI system for plant monitoring and control, and a FactoryTalk Historian for data collection. The plant master controller collects data from all of the Micro820 PLCs via Ethernet\IP, as well as gathering soiling, meteorological, tracker, and substation data from devices throughout the plant via Modbus TCP using its in-rack Prosoft Modbus TCP modules.

.jpg?width=2000&name=Frame%20299(7).jpg)

(1).jpg?width=2000&name=Frame%20299(1)(1).jpg)

(1).jpg?width=2000&name=Frame%20299(2)(1).jpg)

(1).jpg?width=2000&name=Frame%20299(3)(1).jpg)

(1).jpg?width=2000&name=Frame%20299(4)(1).jpg)

(1).jpg?width=2000&name=Frame%20299(6)(1).jpg)

(1).jpg?width=2000&name=Frame%20299(5)(1).jpg)

Application Features

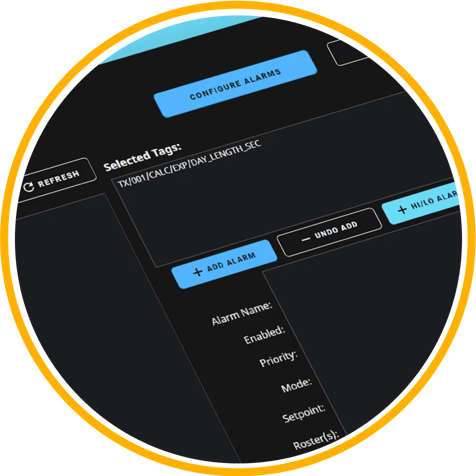

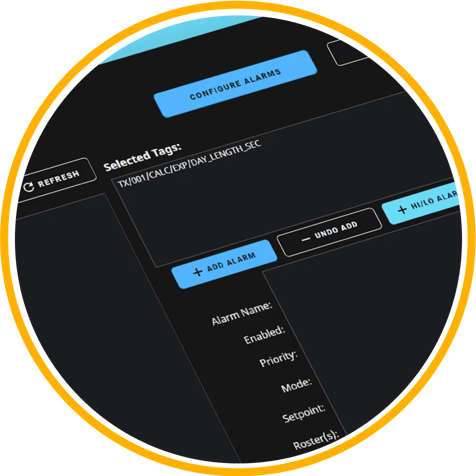

Smart Alarming

Nuisance Alarm Filtering.

We improved the alarming logic across the fleet to prioritize alarms and consolidate repeat alarms into one action.

Built-in Alarm Hierarchy and Dependencies.

This feature allows the client to add dependencies to alarms. When equipment upstream fails or shuts down, the alarms on downstream devices automatically shut off. This enables the client to identify and solve the root cause of the problem, rather than responding to hundreds of subsequent alarms.

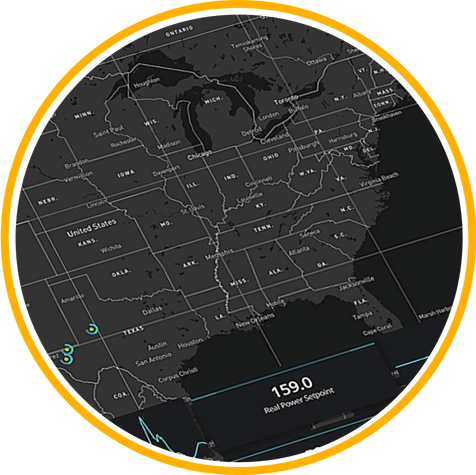

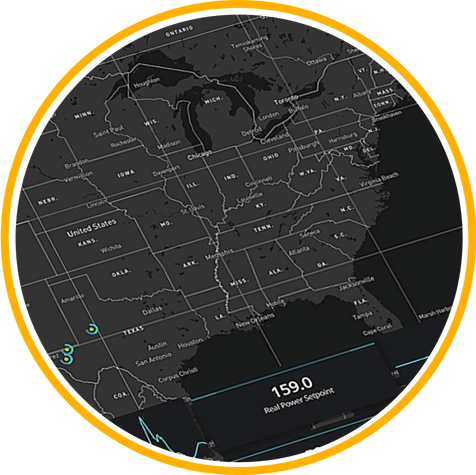

Enterprise-Level Maps

Our team designed custom maps on Mapbox and integrated them with Ignition, so they blend beautifully into the visual application theme.

Our team designed custom maps on Mapbox and integrated them with Ignition, so they blend beautifully into the visual application theme.

KPI’s

Power and Revenue

Our team collaborated with SB Energy to measure power and revenue using KPIs. By having the system display information from both business and operations in one application, decision-makers now have a clear understanding of what's happening across the entire portfolio.

Data Popups

Alongside the KPIs, trending popups allow operators and management to keep up with real-time data patterns and stay aware of site curtailments and revenue losses.

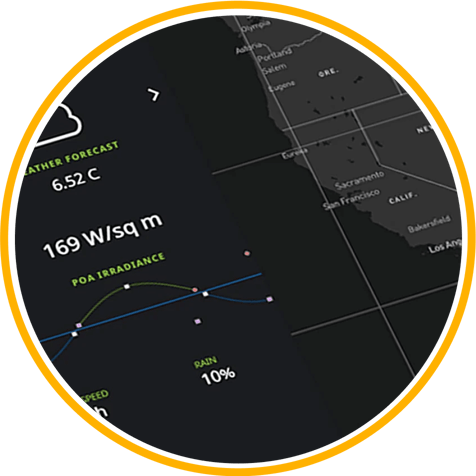

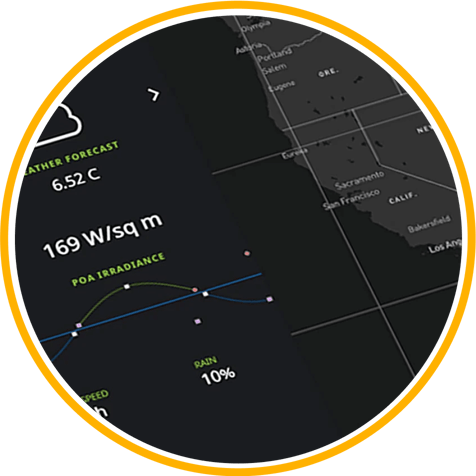

Weather Forecase Integration

We integrated with Open Weather Maps and Windy.com to provide real-time weather updates for each site. We make real-time API calls to Open Weather Maps and Windy.com. We also leverage Windy.com's crisp map displays as needed throughout the system.

We integrated with Open Weather Maps and Windy.com to provide real-time weather updates for each site. We make real-time API calls to Open Weather Maps and Windy.com. We also leverage Windy.com's crisp map displays as needed throughout the system.

The Technology

Allen-Bradley CompactLogix

Prosoft Modbus TCP Module forCompactLogix

Allen-Bradley Micro820

FactoryTalk View SE Servers / Clients

FactoryTalk Historian

Moxa MGate Modbus TCP – Modbus

RTU Gateway

Bonfiglioli Inverters

NexTracker Trackers

Campbell Scientific CR1000 Data Loggers

Schweitzer RTAC

Cisco 2960-X and IE2000 Ethernet Switches

The End Result

The resulting SCADA system successfully connected all components in the solar field with an intuitive interface that made it possible to interact with equipment from various manufacturers in one seamless visual environment. The system required minimal training while providing maximum effectiveness for the operation, control, and troubleshooting of the plant.

Drop us a line

If you'd like to learn more about how we can improve your operations, get in touch!

We love a good challenge and we're ready to help.

.png?width=750&height=679&name=247Support%201(1).png)