CASE STUDY

DEPCOM Power Enterprise Data

Don't Look at the Sun - Look at the Data

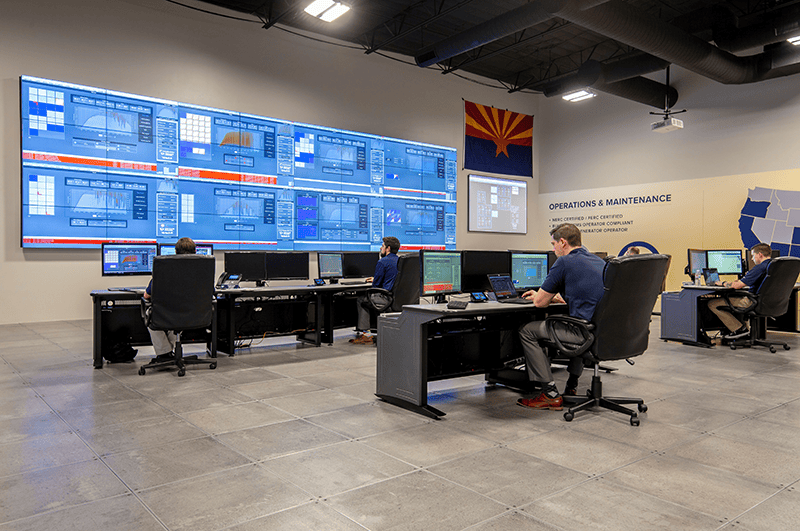

The rapid growth of utility-scale solar installations worldwide is great news for clean energy, but it also creates big headaches for operators managing multiple sites with different technologies and performance quirks. Most teams still juggle spreadsheets and manual data gathering just to get basic performance reports, which is slow and inefficient. This case study shows how Vertech, a leading controls and automation integrator for the solar industry, partnered with DEPCOM Power to roll out Seeq’s advanced analytics software across all sites, giving everyone easy access to connected, user-friendly tools for analyzing data, optimizing performance, and driving smarter decisions.

Enterprise SCADA Streamlines Processes for Renewable Energy

The Protagonist

DEPCOM Power, a Koch Engineered Solutions company, is a leading energy solutions partner specializing in utility-scale solar and energy storage projects, providing full project lifecycle solutions that optimize energy cost, performance, and reliability. The Arizona-based company is committed to providing development, engineering, construction, operations, and maintenance services for utility-scale photovoltaic (PV) solar power plants. With deep technical knowledge and experience, the DEPCOM team is always searching for the best available solutions.

In the wake of global labor shortages and supply chain issues, many manufacturers are turning to system integrators and automation to improve efficiency and productivity. But what does innovation look like for slower, low-volume manufacturing processes that have traditionally been manual?

One such company, American SpiralWeld Pipe (ASWP), engaged systems integrator, Vertech, to implement a comprehensive automation plan for a new state-of-the-art facility in Paris, TX.

The MES Overview displays critical information for all core production lines during the shift. It reports equipment utilization as well as OEE, production status, work order information, and time spent for each core line. Note: Screenshot is simulated and does not represent actual process data

The MES Overview displays critical information for all core production lines during the shift. It reports equipment utilization as well as OEE, production status, work order information, and time spent for each core line. Note: Screenshot is simulated and does not represent actual process data

ASWP, a division of the American Cast Iron Pipe Company, is a spiral-welded steel pipe manufacturer that supports the municipal water and wastewater transmission industry as well as hydroelectric, industrial and power markets. It’s not a small operation. ASWP makes pipes up to 50 feet long with diameters up to 12 feet wide. They have three plant locations that produce a combined average of 6000 pipes, equating to more than 20,000 tons of steel, annually.

ASWP faces the same labor shortages as other manufacturing companies and is always looking for ways to improve production efficiency. Kent Davis, director of business process automation and operational excellence, explained that for ASWP, automation primarily increases quality and throughput.

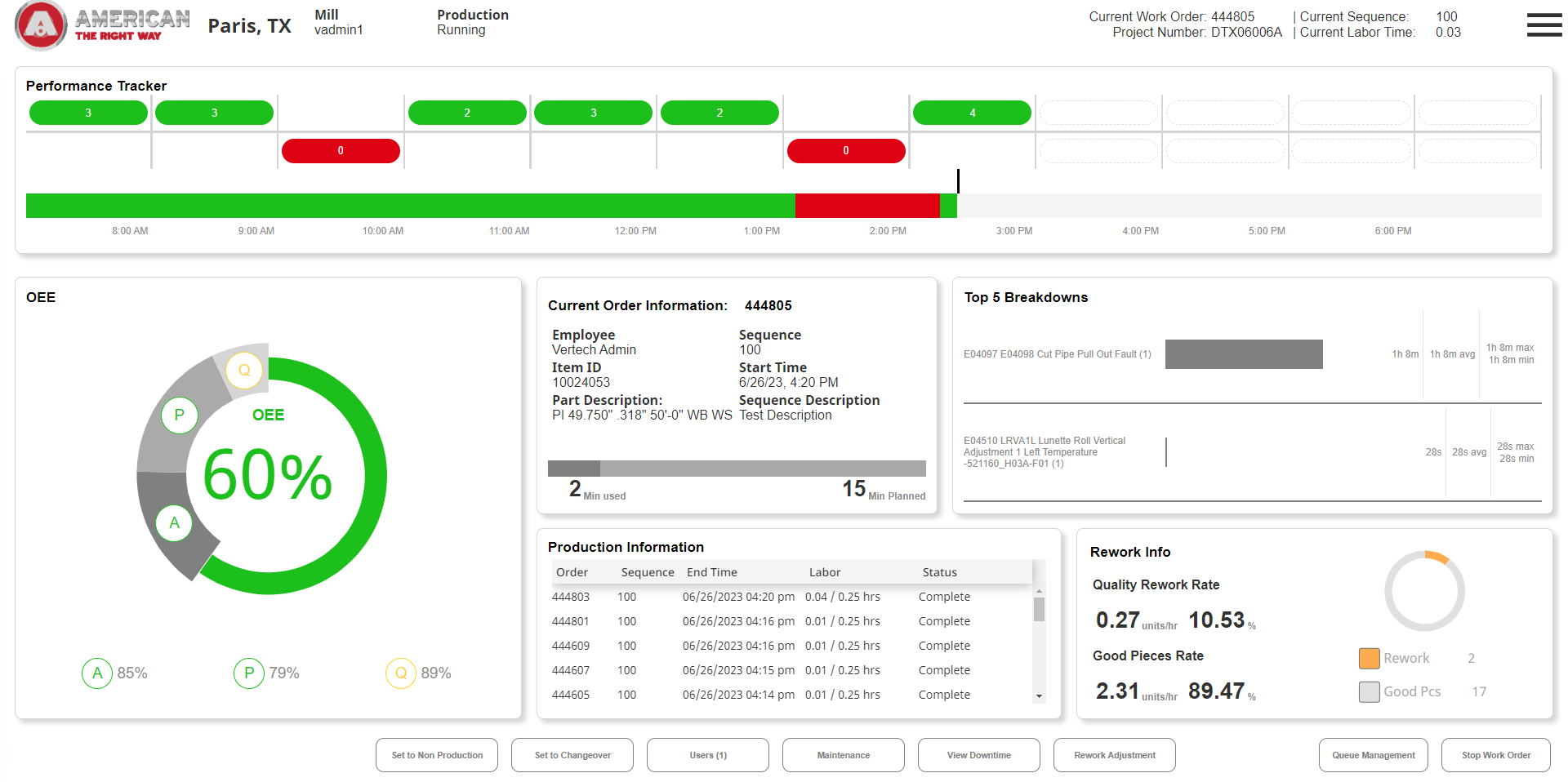

The Mill Overview gives the operator a production overview for that shift. The header displays the current line state, mode, and work order information. The Performance Tracker card shows the status and performance of the line in an hour-by-hour breakdown. The OEE Gauge on the left shows the breakdown of OEE and the contributing variable percentages: Availability, Performance, and Quality. The Current Order Information card shows the active order and operation sequence and the total active time spent on the sequence. The Production Information card shows all orders and their runtime information for the current shift. The Top 5 Breakdowns card shows the accumulated top five downtimes for the current shift and the average, minimum and maximum downtime for the specific downtime reason.

But it takes more of a supporting role when it comes to labor needs. “I want to be clear that the use of automation at ASWP is not a labor reduction focus. We use automation to make the job task easier for the employee… allowing them to make decisions faster and more accurately based on data and facts instead of intuition,” Davis said.

With the large scale of its manufacturing operations, automation also protects ASWP employee safety. Davis said that advances in mechanical automation have allowed them to take a “hands-off” approach to pipe production and transport throughout the facility. Operators interact with machinery HMIs (human-machine Interfaces) rather than the pipes.

ASWP approached Vertech in 2020 to implement supervisory control and data acquisition (SCADA), manufacturing execution (MES) and statistical process control (SPC) systems at their greenfield facility in Paris, TX, and roll out the technology at their Columbia, SC and Flint, MI locations.

Phase 1 of the project, completed in 2021, tackled the SCADA system. The system tracks current and historical production data and funnels it to a centralized control room at the Paris company headquarters. The control room has 18 48-inch industrial monitors that display real-time Industry 4.0 data and analytics. Eventually, all divisional operations will be managed across multiple locations via SCADA, MES, and SPC from the centralized control room.

Phase 2, discussed below, focused on implementing the MES. ASWP wanted a system that tracked labor and production data, transforming it into useful OEE (overall equipment effectiveness), downtime efficiency and resource efficiency metrics.

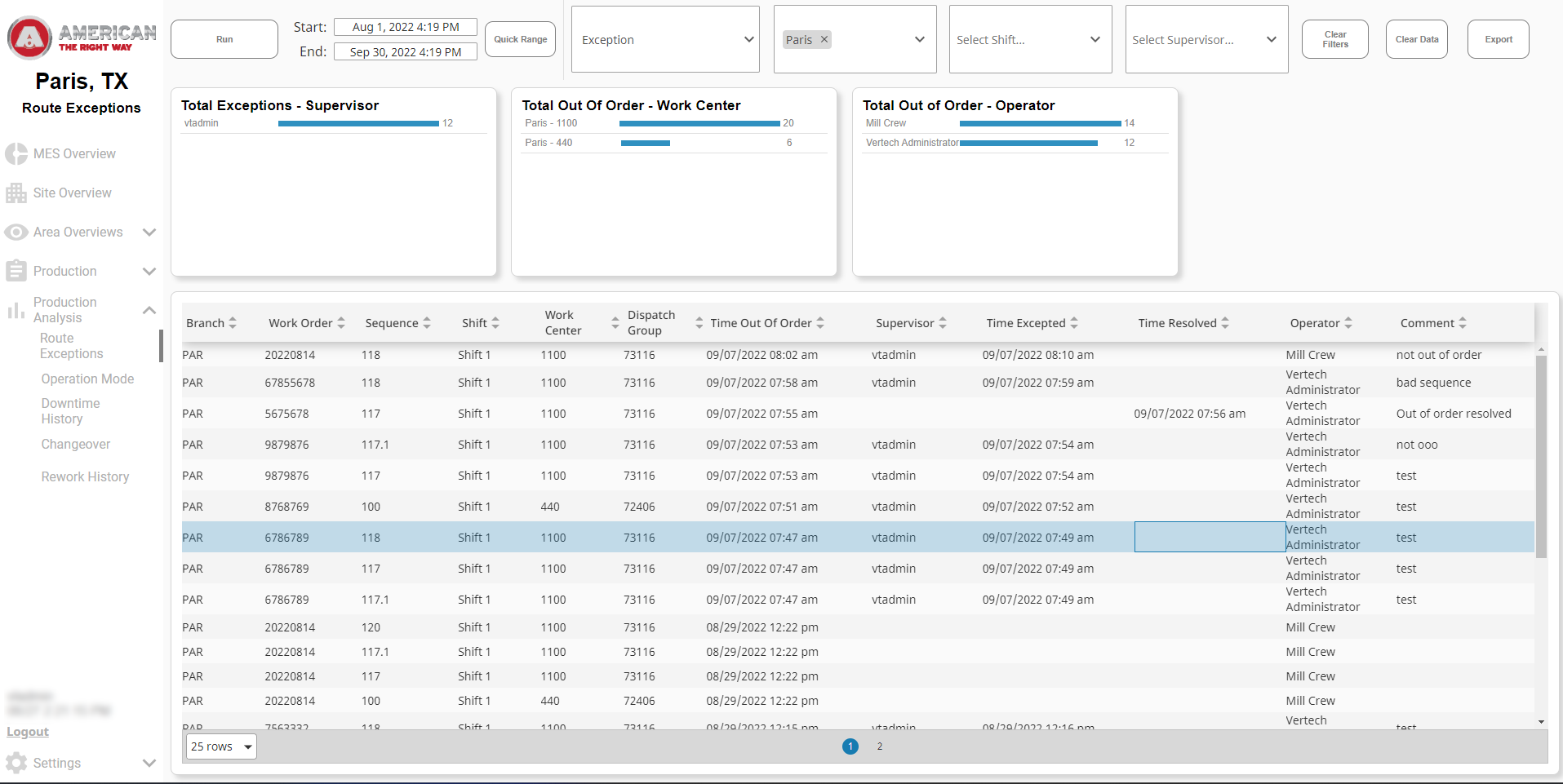

The Route Exceptions Report displays any work order sequences that are out of order as well as resolution time, exception time and other relevant information. When a downstream operation is run before all previous operation sequences have been completed, each incomplete or skipped operation sequence is added to an out-of-order log. These out-of-order operations can be resolved by completing the operation, or a supervisor can mark the route as excepted. When marking an exception, the supervisor can note why the route is excepted.

The Story

The Set-Up

Each solar site generates a massive stream of data — from weather stations and position trackers to power controllers, inverters, and soiling stations. All of this equipment is tied together through PLCs and SCADA systems, providing both real-time and historical process data.

For years, DEPCOM’s performance engineering team had to manually pull, import, and process this data—an error-prone, time-consuming task that slowed down analysis. With so much data already available digitally, they knew the solution was to tap directly into existing systems and automate collection.

The challenge? Finding an advanced analytics platform that could bring everything together and deliver actionable insights across all sites.

The Plot Thickens

DEPCOM’s performance team had long relied on massive spreadsheets to analyze live and historical data. While an industry-standard approach, it's slow, error-prone, and hard to share across teams. They wanted a faster, more reliable way to connect directly to data sources, run advanced analyses, and scale across all sites.

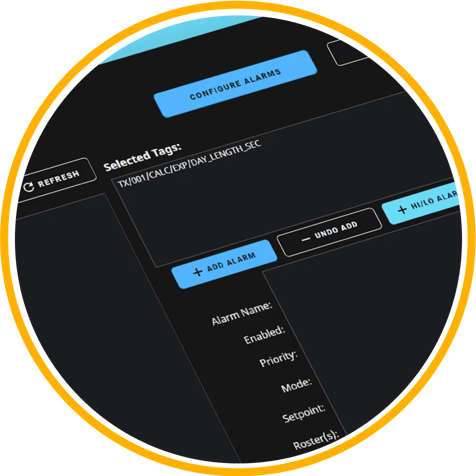

Partnering with Vertech, they outlined must-have features:

- Seamless connectivity to SCADA and historians

- Time-series data support

- Scalability

- User-friendly tools

- Easy reporting

Seeq checked every box, connecting directly to on-prem or cloud data without extra ETL steps and deploying in under an hour. Its browser-based Workbench and Organizer apps make it simple for engineers to collaborate, analyze, and share insights quickly.

To support this platform, DEPCOM also standardized on Canary Labs historian for high-performance time-series storage, built-in Ignition connectivity, and virtually limitless, secure data capacity. Together, these tools gave DEPCOM a solid foundation for enterprise-wide analytics.

The Solution

DEPCOM and Vertech implemented a “hub-and-spoke” architecture, with each site running Ignition locally and feeding data into a centralized Canary enterprise historian and Seeq Server. This setup let DEPCOM monitor 5 GW of generation capacity nationwide from a single location. Vertech handled the Seeq installation and configuration in minutes, connecting directly to the enterprise historian via OPC-HDA.

To make the data easy to use, Vertech built a unified asset tree model so engineers could quickly find, reuse, and “swap” analyses across similar assets. Seeq’s Workbench and Organizer tools let users cleanse data, run analyses, and build dashboards and reports in a browser. No more massive spreadsheets!

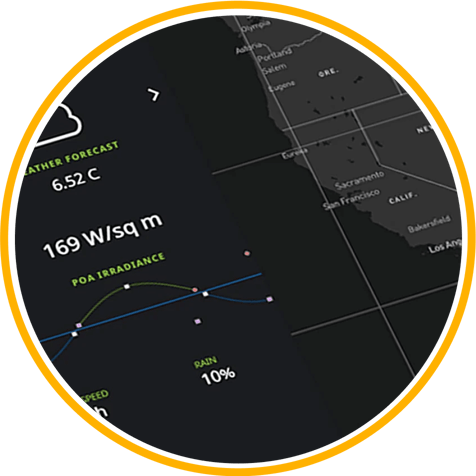

With the system live, DEPCOM built dashboards showing daily, monthly, and annual KPIs like POA irradiance, generation totals, and module temperatures. They also automated ASTM performance calculations and soiling analyses to optimize cleaning intervals and track inverter uptime.

The result: faster, cleaner insights that free engineers from manual data wrangling and give clients timely, accurate performance reports.

Screens Designed

MES Overview

The MES Overview displays critical information for all core production lines during the shift. It reports equipment utilization as well as OEE, production status, work order information, and time spent for each core line. Note: Screenshot is simulated and does not represent actual process data.

Mill Overview

The Mill Overview gives the operator a production overview for that shift. The header displays the current line state, mode, and work order information. The Performance Tracker card shows the status and performance of the line in an hour-by-hour breakdown. The OEE Gauge on the left shows the breakdown of OEE and the contributing variable percentages: Availability, Performance, and Quality. The Current Order Information card shows the active order and operation sequence and the total active time spent on the sequence. The Production Information card shows all orders and their runtime information for the current shift. The Top 5 Breakdowns card shows the accumulated top five downtimes for the current shift and the average, minimum and maximum downtime for the specific downtime reason.

The Mill Overview gives the operator a production overview for that shift. The header displays the current line state, mode, and work order information. The Performance Tracker card shows the status and performance of the line in an hour-by-hour breakdown. The OEE Gauge on the left shows the breakdown of OEE and the contributing variable percentages: Availability, Performance, and Quality. The Current Order Information card shows the active order and operation sequence and the total active time spent on the sequence. The Production Information card shows all orders and their runtime information for the current shift. The Top 5 Breakdowns card shows the accumulated top five downtimes for the current shift and the average, minimum and maximum downtime for the specific downtime reason.

KPI’s

Power and Revenue

Our team collaborated with SB Energy to measure power and revenue using KPIs. By having the system display information from both business and operations in one application, decision-makers now have a clear understanding of what's happening across the entire portfolio.

Data Popups

Alongside the KPIs, trending popups allow operators and management to keep up with real-time data patterns and stay aware of site curtailments and revenue losses.

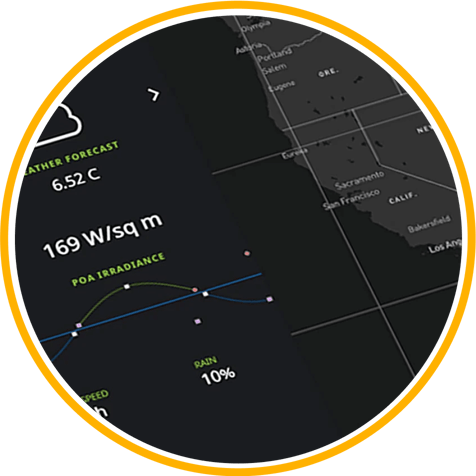

Weather Forecase Integration

We integrated with Open Weather Maps and Windy.com to provide real-time weather updates for each site. We make real-time API calls to Open Weather Maps and Windy.com. We also leverage Windy.com's crisp map displays as needed throughout the system.

We integrated with Open Weather Maps and Windy.com to provide real-time weather updates for each site. We make real-time API calls to Open Weather Maps and Windy.com. We also leverage Windy.com's crisp map displays as needed throughout the system.

The Happy Ending

By moving from manual spreadsheets to an enterprise-wide analytics platform, DEPCOM completely changed the way its team works. What used to take hours of data gathering and number crunching is now automated, accurate, and available on demand. Engineers can focus on finding opportunities to boost performance instead of just collecting data, and site owners get clear, timely reports that drive better decisions.

Partnering with Vertech and choosing Seeq gave DEPCOM a scalable, future-proof solution that grows with their portfolio. With centralized data, standardized models, and easy-to-use tools, they can roll out new analyses, spot issues earlier, and keep sites running at peak performance, no matter how big the fleet gets.

Drop us a line

If you'd like to learn more about how we can improve your operations, get in touch! We love a good challenge and we're ready to help.

.png?width=750&height=679&name=247Support%201(1).png)