CASE STUDY

MillerKnoll

Modern MES System

TO STREAMLINE MANUFACTURING OPERATIONS AND DISPLAY LIVE DATA

MillerKnoll implemented a Manufacturing Execution System to facilitate and track production while playing well with their existing automation software.

Enterprise SCADA Streamlines Processes for Renewable Energy

The Protagonist

MillerKnoll is a leading designer and manufacturer of high-quality furniture for offices, homes, healthcare facilities and more.

With a portfolio of dynamic design brands and locations all over the world, MillerKnoll has been at the forefront of design for over a century.

The Story

In the Beginning...

The mission was pretty clear-cut. MillerKnoll needed an order execution system that could handle their entire production process, including product sequencing, schedule management, inventory management and more. Plus, it had to play nice with other existing Ignition software projects in their MillerKnoll Live Factory ecosystem.

The Plot Thickens

Now, here's where things get tricky. MillerKnoll has a big family of brands that span multiple locations and have their own processes and systems. They needed an MES system that could work with their legacy systems as well as a variety of ERP systems.

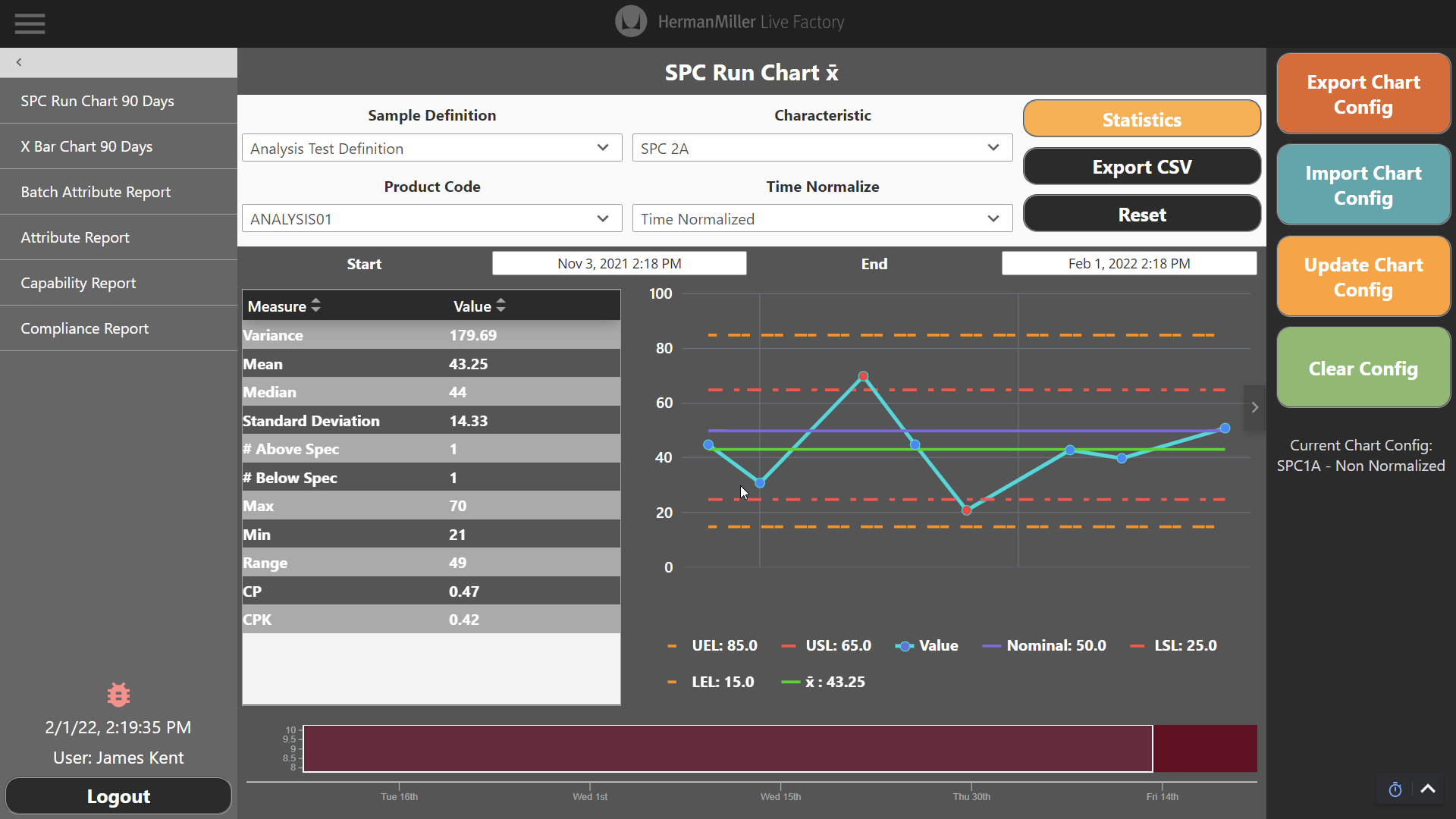

Enter Vertech. With our extensive Ignition experience and existing knowledge of MillerKnoll's infrastructure through our SPC (statistical process control) project for them, we were ready to tackle this challenge head-on.

The Happy Ending

Application Features

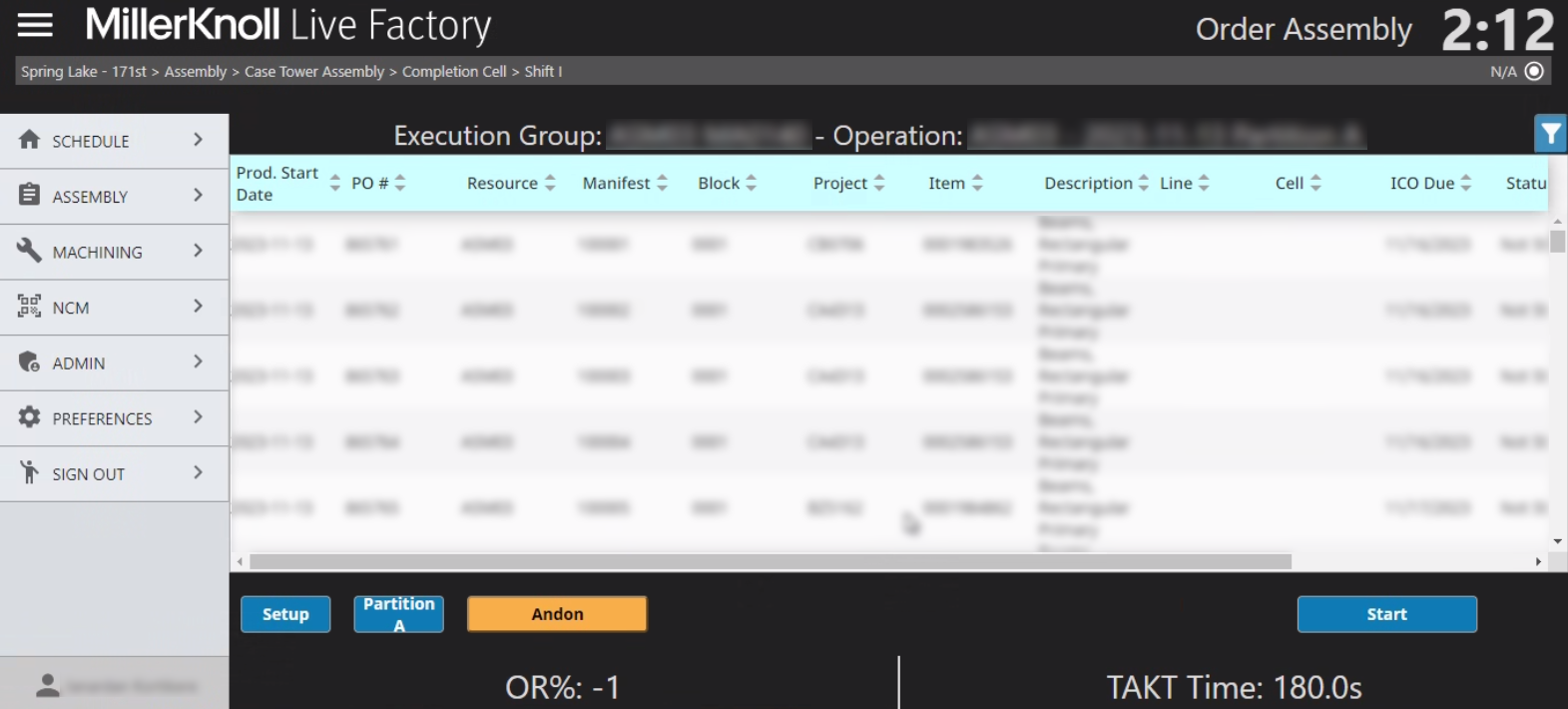

Automated Order Schedules

We created automated order schedules for each manufacturing site and for individual lines within the site. Schedulers and line supervisors can create their own dynamic sequencing rules based on the characteristics of the order. This means the system can shuffle the order and part flow of manufacturing items to different machine centers, optimizing performance. It identifies and addresses the root cause of problems, rather than responding to hundreds of subsequent alarms.

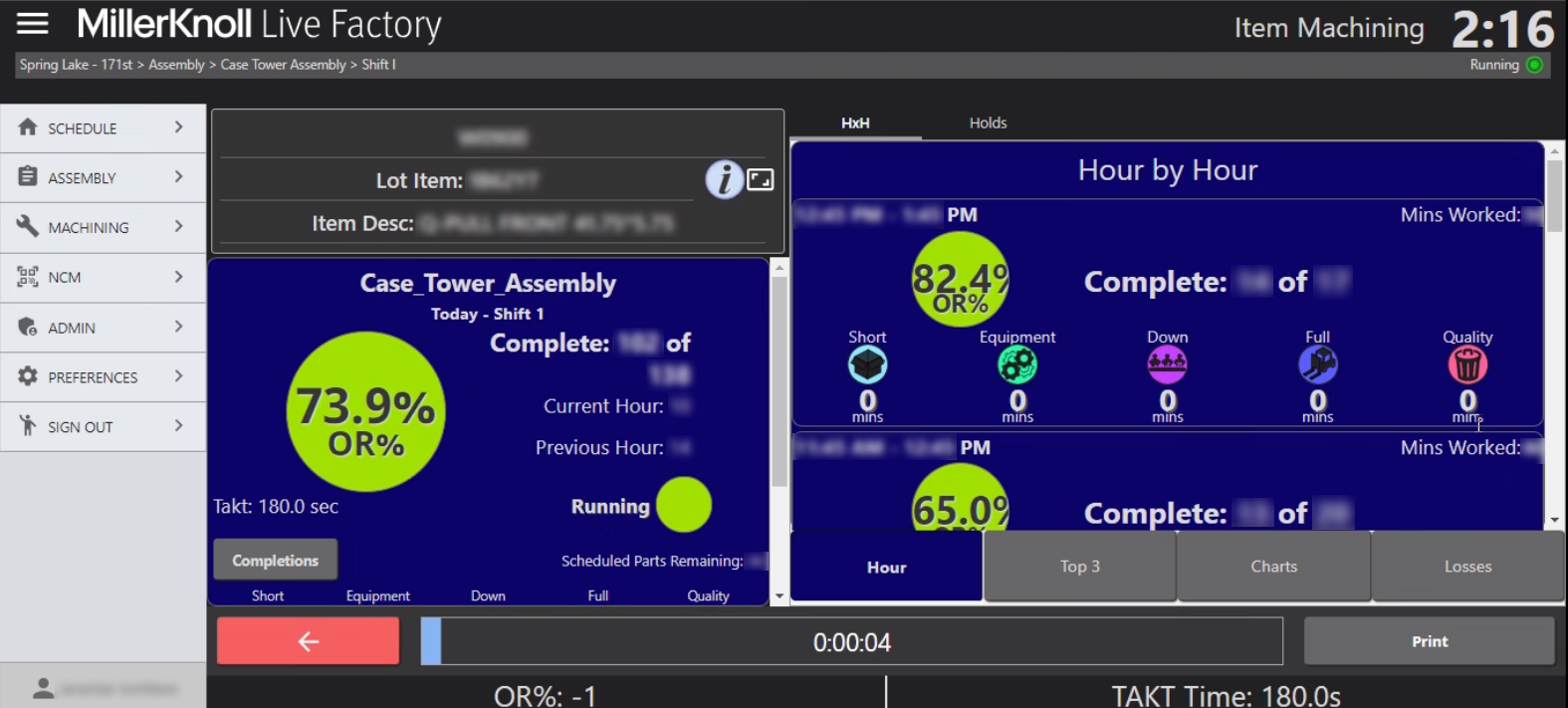

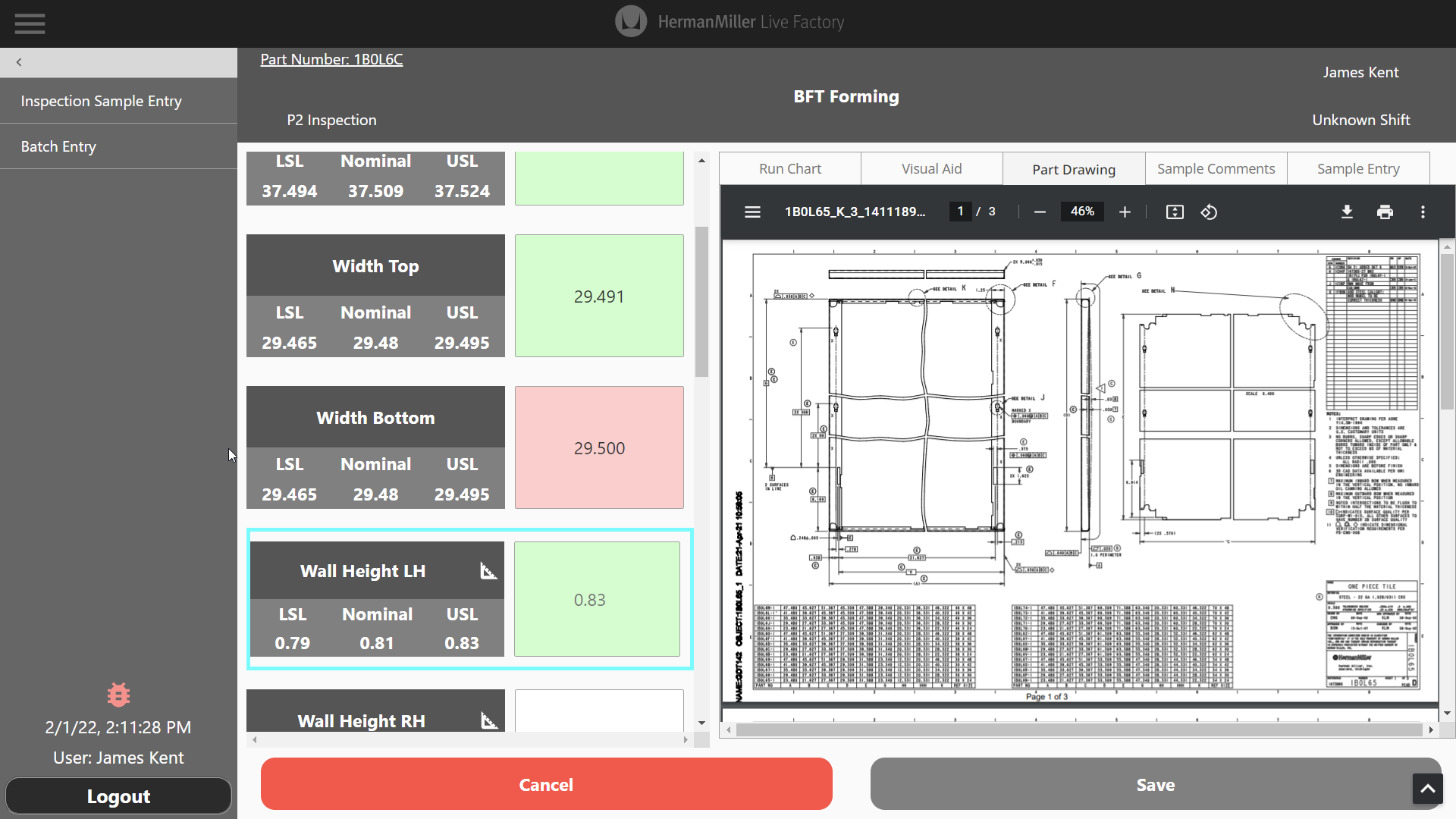

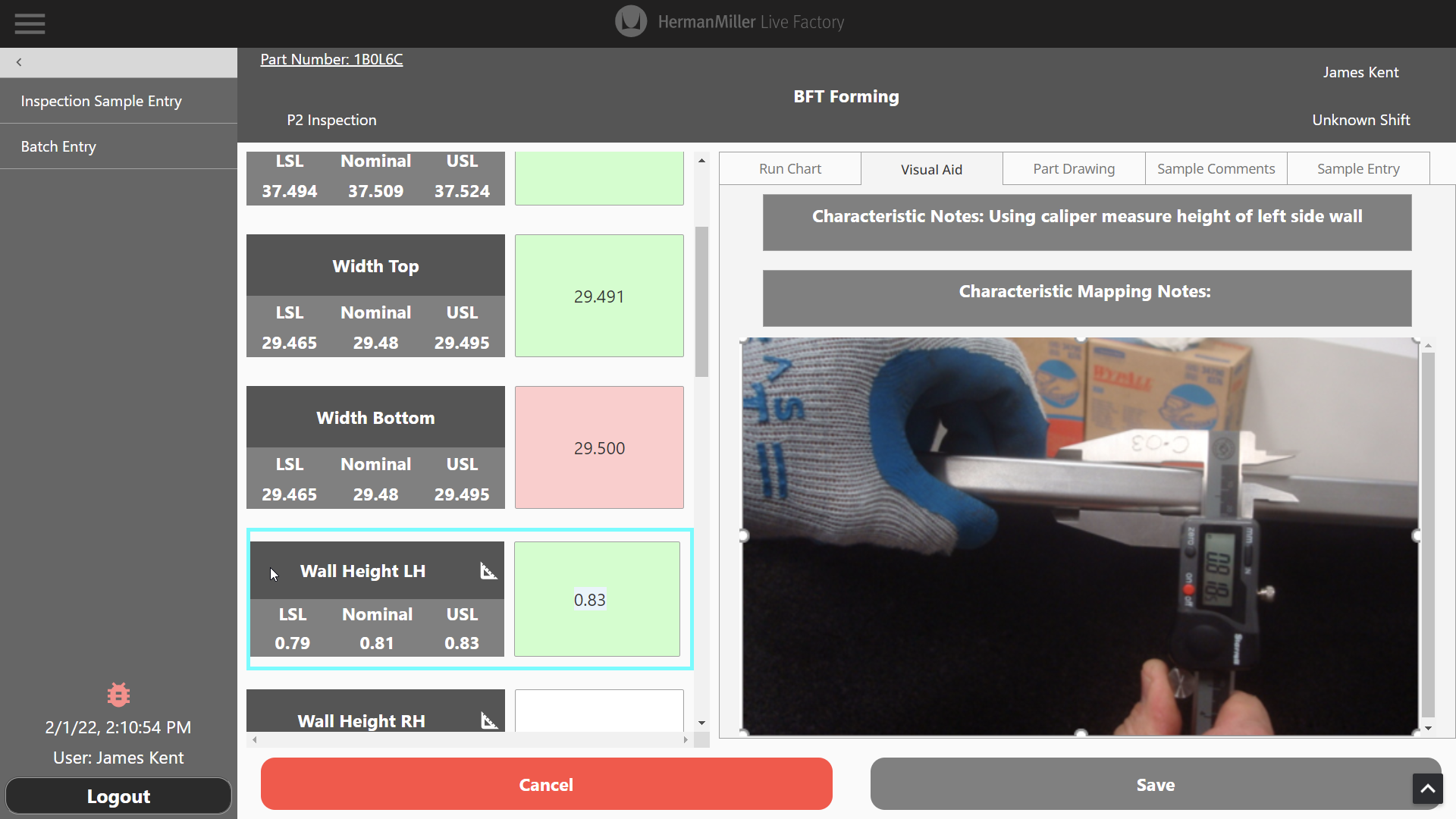

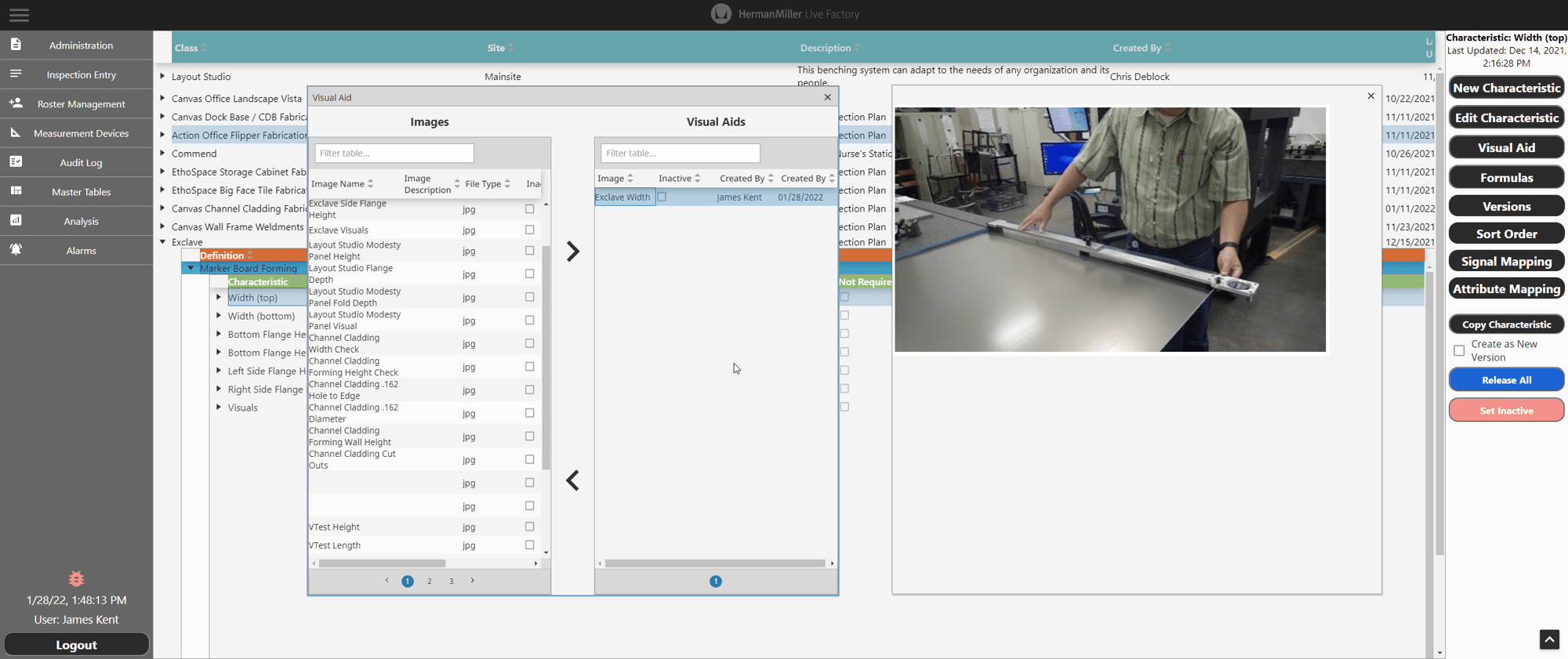

Operator Interface

We provided a front-end interface that contains all the info an operator needs at a glance. This includes bills of materials, manufacturing holds, part defects, inspections and work instructions. By recording all this data and tracking its flow, we replaced paper-based operations with a system that can pull up every detail of what happened in an order.

We provided a front-end interface that contains all the info an operator needs at a glance. This includes bills of materials, manufacturing holds, part defects, inspections and work instructions. By recording all this data and tracking its flow, we replaced paper-based operations with a system that can pull up every detail of what happened in an order.

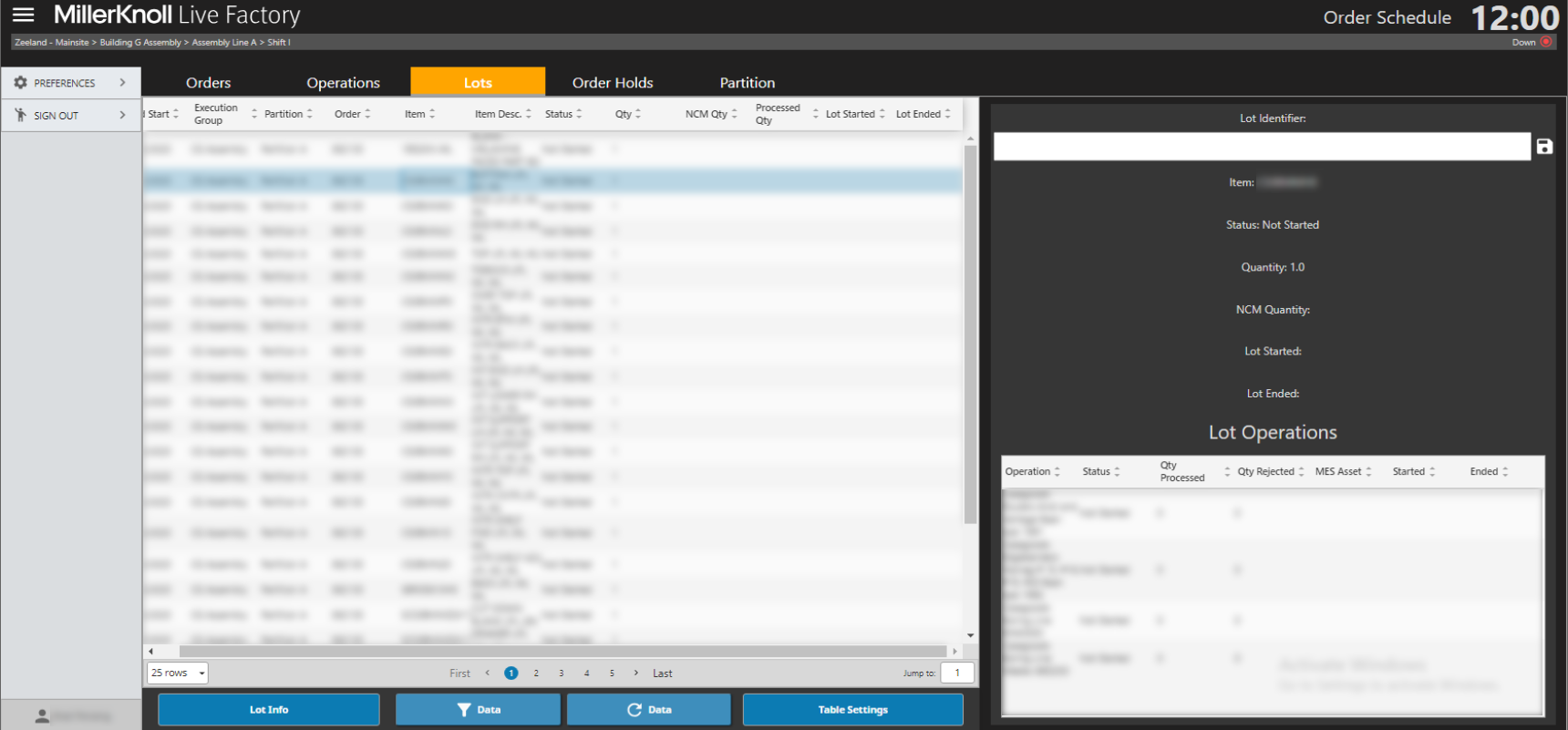

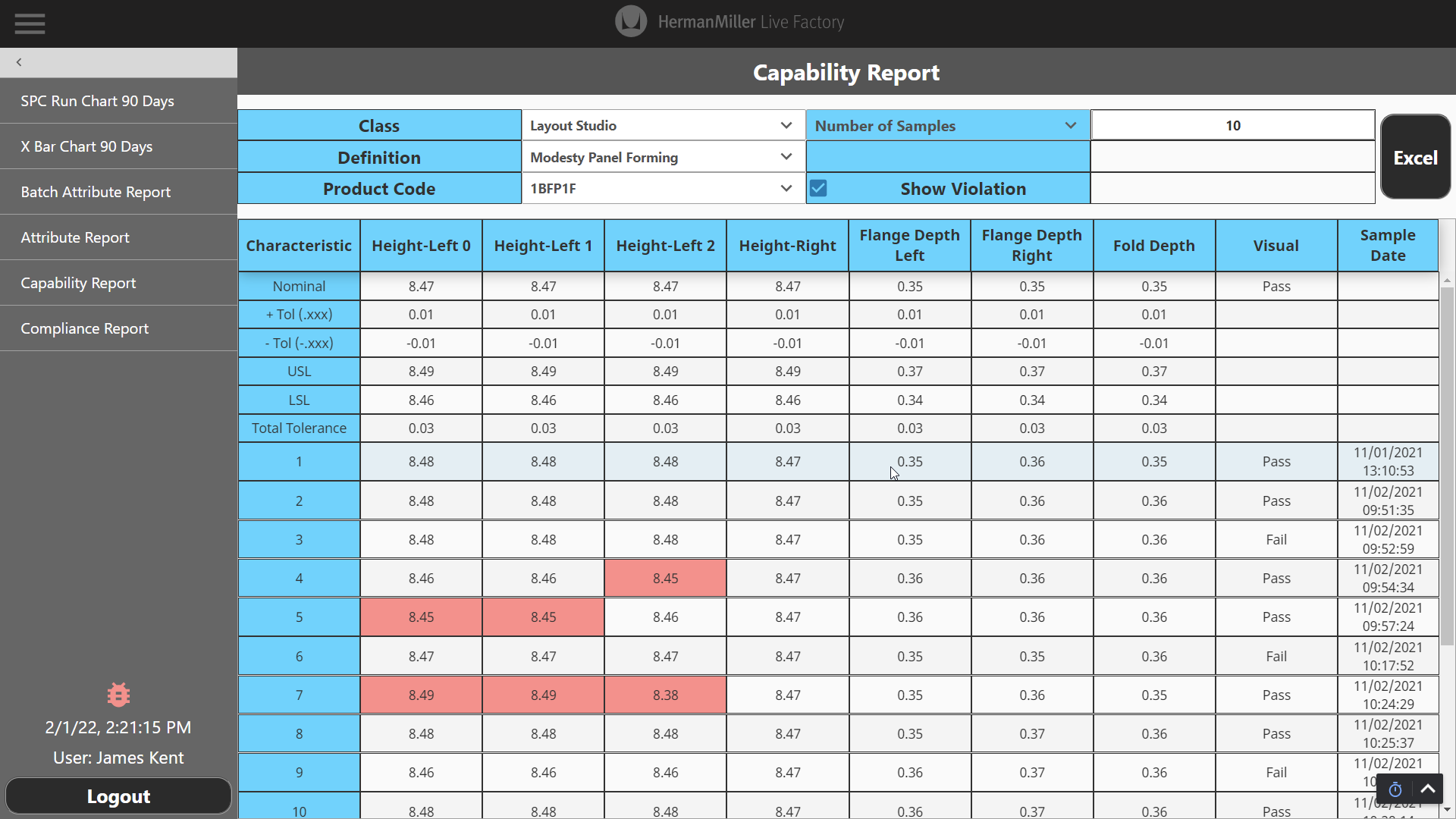

Contextualized Production DATA

We split and optimized production into time-based slices to ensure each work order would satisfy the required total number of shipped products for the day. The system can identify the 1000s of parts that are required to satisfy multiple customer orders and split them into lots that are tracked and recorded against inventory.

Rework Tracking

The system tracks the performance and rework percentage across multiple part and line configurations, then reports which lines are having the most difficulty reaching performance metrics such as Takt time. Operators can tell what has been produced, where it needs to go, and what reworked parts are ready to be transferred back into production.

The system tracks the performance and rework percentage across multiple part and line configurations, then reports which lines are having the most difficulty reaching performance metrics such as Takt time. Operators can tell what has been produced, where it needs to go, and what reworked parts are ready to be transferred back into production.

ERP Sync

Lastly, the system executes transactions against various ERP systems that validate customer and order shipment data. Staff is able to stay up to date with order fulfillment and see how specific production issues might impact delivery timelines.

Lastly, the system executes transactions against various ERP systems that validate customer and order shipment data. Staff is able to stay up to date with order fulfillment and see how specific production issues might impact delivery timelines.

Drop us a line

If you'd like to learn more about how we can improve your operations, get in touch! We love a good challenge and we're ready to help.

.png?width=750&height=679&name=247Support%201(1).png)